I-10MM UKUYA kwi-130MM yokuSila iBhola yentsimbi yokuSila kwiMigodi yesinyithi yeBall Mill kunye neZityalo zesamente

Ingcaciso yeMveliso

Inkqubo yokuvelisa

Ibhola ephoswayo, ekwabizwa ngokuba yibhola yokugaya, yenziwe ngentsimbi ye-scrap, isinyithi esilahliweyo, kunye nezinye izinto ezilahliweyo. Ezi zinto zikhankanywe ngasentla zinyibilike kakhulu kwaye ziqhuba umsinga oqhubekayo emva kokufudumeza. Ngexesha lokunyibilikisa, inani elikhulu lezinto zetsimbi ezifana ne-vanadium, isinyithi kunye ne-manganese zongezwa kuqala kwi-flue gas ukufezekisa isivuno esinqwenelekayo nesigqitywe kwangaphambili. Ezi zinto ke zinokuthi zigalele intsimbi enyibilike kakhulu kwimodeli yomgca wemveliso yesityalo sokwenza intsimbi.

Isicelo

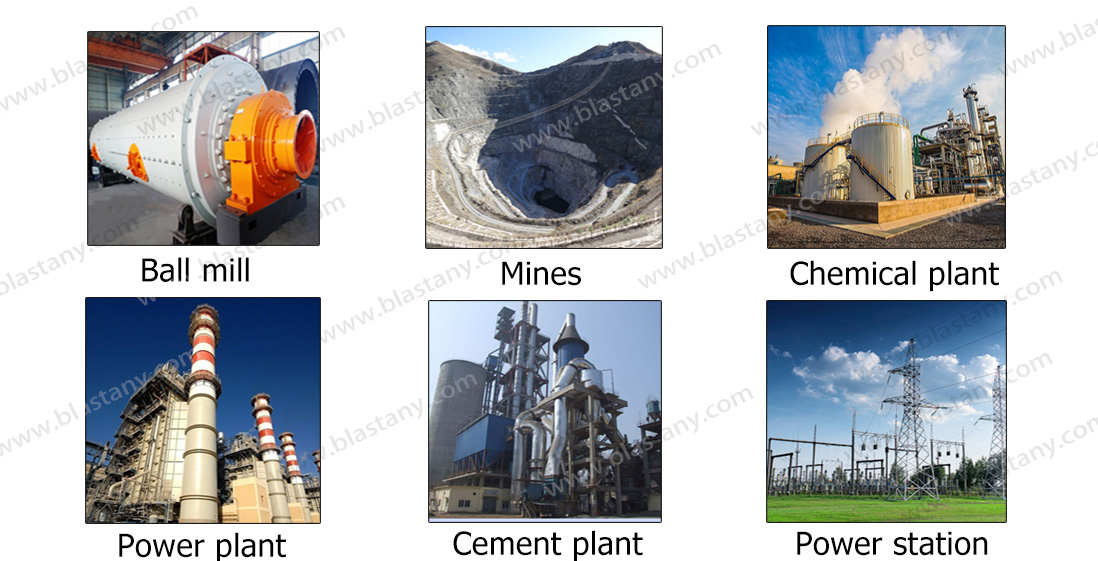

Ibhola yentsimbi yokuphosa inokusetyenziswa kakhulu kwizicelo ezahlukeneyo, kubandakanya

Umzi-mveliso wesanti yesilika/umzi-mveliso wesamente/umatshini weMichiza/umatshini wamandla/iMigodi/Izikhululo zamandla

/Amashishini eChemical/Igrinding mill/Ball mill/Coal Mill

Ukuqaliswa kweemveliso zebhola zentsimbi

Iibhola zentsimbi eziphoswe nge-Chrome ziibhola zemidiya ezigayiweyo eziqulethe ipesenti ethile yechromium, ezize zohlulwe zibe ziibhola zentsimbi eziphoswe ngechromium ephezulu, iibhola zentsimbi eziphoswe ngechromium ephakathi kunye neebhola zentsimbi eziphoswe ngechromium ephantsi. Iibhola zentsimbi eziphoswe ngechromium zohlulwe zibe ziiBhola zentsimbi eziPhezulu zeChromium, iiBhola zentsimbi zeChromium eziPhakathi kunye kunye neeBhola zentsimbi zeChromium eziphantsi. Ngophawu lobunzima obuphezulu, ukunxiba okuphantsi, kunye nokuqhekeka okuphantsi, iibhola ezigayiweyo zentsimbi zisetyenziswa ikakhulu kwishishini lesamente, kwishishini lemigodi, kwishishini lesinyithi, ishishini lokuvelisa amandla kunye noshishino lokwakha.

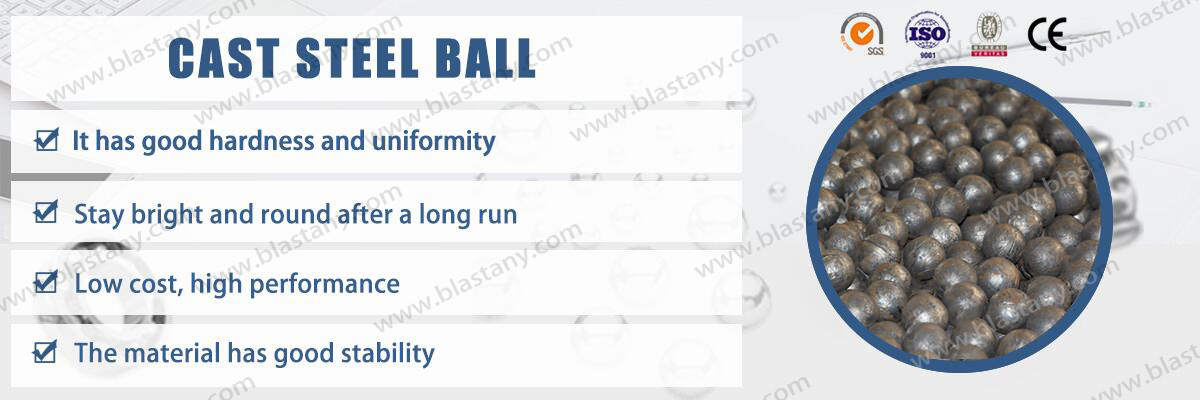

Cast Iimpawu zeBhola yentsimbi

1, Izinto ekrwada zonke zithwele izilahlwa zentsimbi, eziqulethe ubhedu, i-molybdenum, i-nickel kunye nezinye izinto ezixabisekileyo zentsimbi, ezinokuthi ziphucule ngokufanelekileyo ukwakheka kwe-matrix yebhola yentsimbi.

I-2, iimveliso zethu ziveliswa yi-medium frequency frequency furnace enokuqinisekisa ngokufanelekileyo ukuzinza kwezinto. Iibhola azikho lula ukuzixobula kunye nokonakala ngexesha lokusetyenziswa. Nokuba ingahlala iqaqambile kwaye ingqukuva emva kwexesha elide ibaleka.

3, Umgca wemveliso yokucima i-oyile ephezulu kakhulu ephezulu kakhulu yamkelwa kunyango lobushushu, eqinisekisa ubulukhuni obuhle kunye nokufana kweemveliso.

Iindlela ezintathu zokwenza iibhola zentsimbi

1. Iindlela ezintathu zokwenza ibhola yentsimbi

Kukho iintlobo ezintathu zeenkqubo zokwenziwa kwebhola yentsimbi: ukuphosa, ukubunjwa, kunye nokuqengqeleka.

(1) Ukuphosa: Umgangatho weebhola zentsimbi eziphosiweyo ikakhulu zixhomekeke kumxholo wechromium. Kwiminyaka yakutshanje, ukunyuka kwexabiso le-chromium, ukukhuselwa kwendalo, kunye nezinye izinto eziye zabangela ukunyuka kweendleko zeebhola zensimbi.

(2) Ukubumba: Ukusebenzisa intsimbi ephezulu yemanganese njengemathiriyeli ekrwada, iihamile zokubumba ipneumatic kunye nokubumba ibhola zisetyenziselwa ukwenza iibhola zentsimbi. Iibhola zentsimbi ezibunjiweyo zinokuhlanganiswa okufanelekileyo kwekhabhoni ephezulu, i-manganese, i-chromium, kunye nezinye izinto ze-alloy, kwaye zinobunzima obuqinileyo kwimveliso yonyango lobushushu, umehluko omncinci wobunzima phakathi kwangaphakathi nangaphandle, kunye nokwahlukana kwexabiso lempembelelo, eyenza iibhola ezibunjiweyo zomelele ngaphezu kweebhola eziphosiweyo.

(3).

| Into | Ukwakhiwa kwemichiza(%) | |||||||||

| C | Si | Mn | Cr | P | S | Mo | Cu | Ni | ||

| I-chrome ephezulu phosa iibhola ze-gri nding | ZQCr12 | 2.0-3.0 | 0.3-1.2 | 0.2-1.0 | 11-13 | ≤0.10 | ≤0.10 | 0-1.0 | 0-1.0 | 0-1.5 |

| ZQCr15 | 2.0-3.0 | 0.3-1.2 | 0.2-1.0 | 14-17 | ≤0.10 | ≤0.10 | 0-1.0 | 0-1.0 | 0-1.5 | |

| ZQCr20 | 2.0-2.8 | 0.3-1.0 | 0.2-1.0 | 18-22 | ≤0.10 | ≤0.08 | 0-2.0 | 0-1.0 | 0-1.5 | |

| ZQCr26 | 2.0-2.8 | 0.3-1.0 | 0.2-1.0 | 22-28 | ≤0.10 | ≤0.08 | 0-2.5 | 0-2.0 | 0-1.5 | |

| I-chrome ephakathi iibhola zokusila ls | ZQCr7 | 2.0-3.2 | 0.3-1.5 | 0.2-1.0 | 6.0-10 | ≤0.10 | ≤0.08 | 0-1.0 | 0-0.8 | 0-1.5 |

| I-chrome ephantsi iibhola zokusila | ZQCr2 | 2.0-3.6 | 0.3-1.5 | 0.2-1.0 | 1.0-3.0 | ≤0.10 | ≤0.08 | 0-1.0 | 0-0.8 | |

Imilinganiselo yokujula yechromium ephezulu (Iparamitha yeBhola yeChrome ePhezulu)

| Idayamitha yegama | Ubunzima bebhola enye kumndilili (g) | Ubungakanani/ MT | Ubulukhuni bomphezulu(HRC) | Uvavanyo lwempembelelo yokunyamezela (Amaxesha) |

| φ15 | 13.8 | 72549 | >60 | >10000 |

| φ17 | 20.1 | 49838 | >10000 | |

| φ20 | 32.7 | 30607 | >10000 | |

| φ25 | 64 | 15671 | >10000 | |

| φ30 | 110 | 9069 | >10000 | |

| φ40 | 261 | 3826 | >10000 | |

| φ 50 | 510 | 1959 | >10000 | |

| φ60 | 882 | 1134 | >10000 | |

| φ70 | 1401 | 714 | >10000 | |

| φ80 | 2091 | 478 | >58 | >10000 |

| φ90 | 2977 | 336 | >10000 | |

| φ100 | 4084 | 245 | >8000 | |

| φ120 | 7057 | 142 | >8000 | |

| φ130 | 8740 | 115 | >8000 |

Iindidi zeemveliso