AISI1010/1015/1085 High/Low carbon steel ibhola 0.8 mm – 50.8 mm Ibhola yentsimbi yeCarbon yeebheringi zeebheringi ivili

Ingcaciso yeMveliso

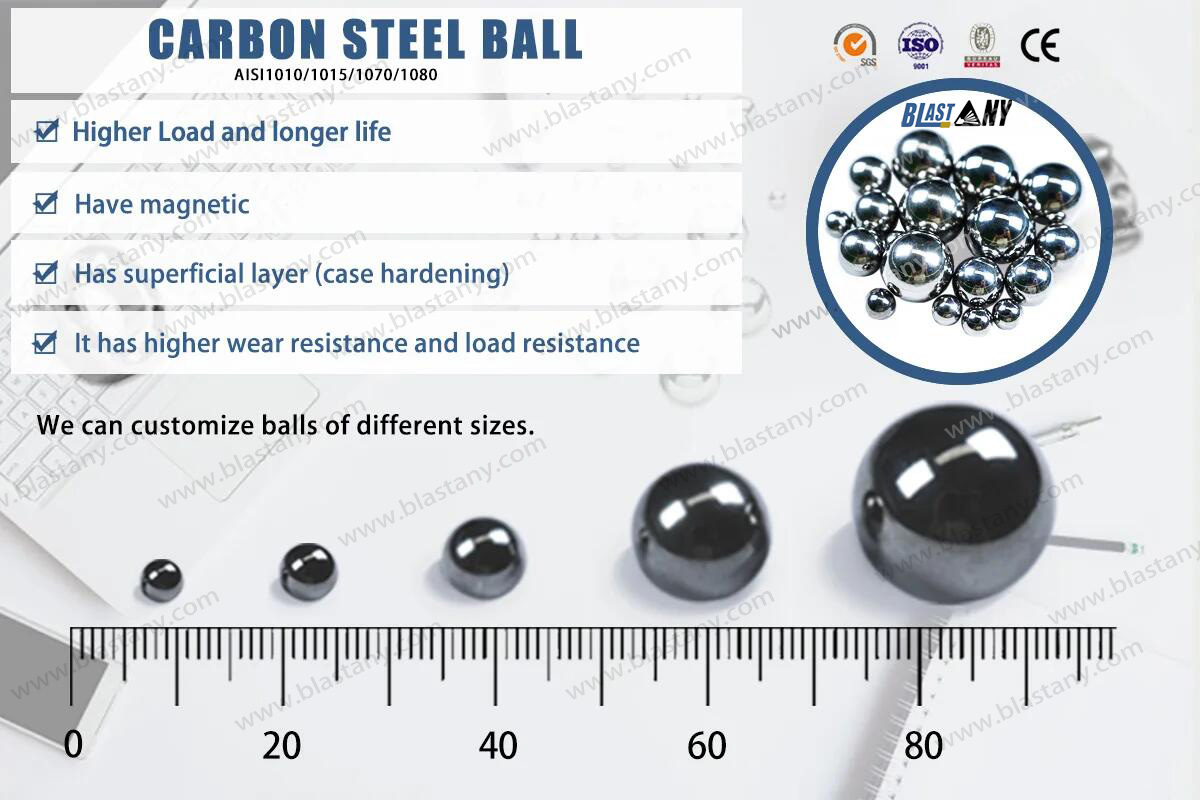

Ibhola yentsimbi yeCarbon ephantsi.

| Izinto eziphathekayo | AISI1010/1015 |

| Ubungakanani Uluhlu | 0.8mm-50.8mm |

| IBanga | G100-G1000 |

| Ukuqina | HRC:55-65 |

Ingcaciso yeMveliso

Iimbonakalo:

zinezibuthe, iiBhola zentsimbi yeCarbon inomaleko ongaphezulu (ukuqina kwetyala), ngelixa indawo yangaphakathi yebhola ihlala ithambile ye-metallographic tructure yi-ferrite, ipakethe rhoqo ngeoyile. Ngokuqhelekileyo i-electroplating xa ingaphandle kwendawo, inokuthi ifakwe nge-zinc, igolide, i-nickel, i-chrome kunye nokunye. inomsebenzi oqinileyo wokuchasana nokunxiba .Ukuthelekisa : ukuxhathisa ukunxiba kunye nobunzima akulunganga kunokuthwala ibhola yentsimbi ( I - HRC ye GCr15 ibhola yentsimbi yi 60- 66 ) : ke , ubomi bufutshane ngokwentelekiso .

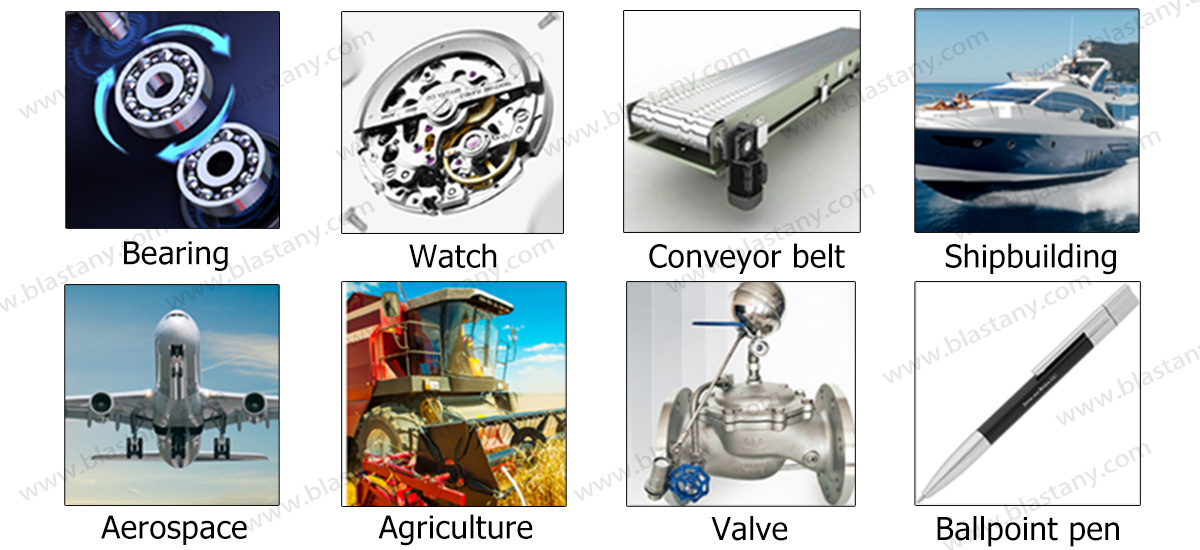

Isicelo:

I-1010/1015 ibhola yentsimbi ye-carbon yibhola yentsimbi eqhelekileyo, inexabiso eliphantsi, ukuchaneka okuphezulu kunye nokusetyenziswa okubanzi. Isetyenziswa kwibhayisekile, iibheringi, ivili letsheyini, umsebenzi wobugcisa, ishelufa, ibhola eguquguqukayo, iibhegi, izinto ezincinci zehardware, ingasetyenziselwa ukuhlikihla ezinye medium.Castors, Dressers' Bearings, Locks, Oilers and Grease Cups, Skates.drawers Slides And Window Rolling Bearings, Toys, Convenitings.

| UHLOBO LOMSEBENZI | C | Si | Mn | P (MAX.) | S (MAX.) |

| I-AISI 1010 (C10) | 0.08-0.13 | 0.10-0.35 | 0.30-0.60 | 0.04 | 0.05 |

| I-AISI 1015 (C15) | 0.12-0.18 | 0.10-0.35 | 0.30-0.60 | 0.04 | 0.05 |

Ibhola yentsimbi yeCarbon ephezulu

| Izinto eziphathekayo | I-AISI1085 |

| Ubungakanani Uluhlu | 2mm-25.4mm |

| IBanga | G100-G1000 |

| Ukuqina | HRC 50-60 |

Ingcaciso yeMveliso

Iimbonakalo:

I-AISI1070/1080 Iibhola zeCarbon Steel, & Iibhola eziphezulu ze-carbon steel zinenzuzo ephawulekayo ngokubhekiselele kwi-index yobunzima obupheleleyo, malunga ne-60/62 HRC kwaye inikezela ukunxiba okuphezulu kunye nokumelana nomthwalo xa kuthelekiswa neebhola zetsimbi eziqhelekileyo eziphantsi kwekhabhoni.

(1)Undoqo-lukhuni

(2)Ukunganyangeki okuphantsi kuhlaselo oludlekayo

(3) Umthwalo ophakamileyo kunye nobomi obude kunebhola yensimbi ye-carbon ephantsi

Isicelo:

Izixhobo zebhayisekile, iibheringi zeebhola zefenitshala, izikhokelo zokutyibilika, amabhanti okuhambisa, amavili omthwalo onzima, iiyunithi zokuxhasa ibhola. Iibheringi ezichanekileyo ezisezantsi, iibhayisekile kunye nezinto zemoto, ii-agitators, izityibilizi, iipolishi kunye noomatshini bokungqusha, iibheringi zokuchaneka okuphantsi.

| UHLOBO LOMSEBENZI | C | Si | Mn | P (MAX.) | S (MAX.) |

| I-AISI 1070 (C70) | 0.65-0.70 | 0.10-0.30 | 0.60-0.90 | 0.04 | 0.05 |

| I-AISI 1085 (C85) | 0.80-0.94 | 0.10-0.30 | 0.70-1.00 | 0.04 | 0.05 |

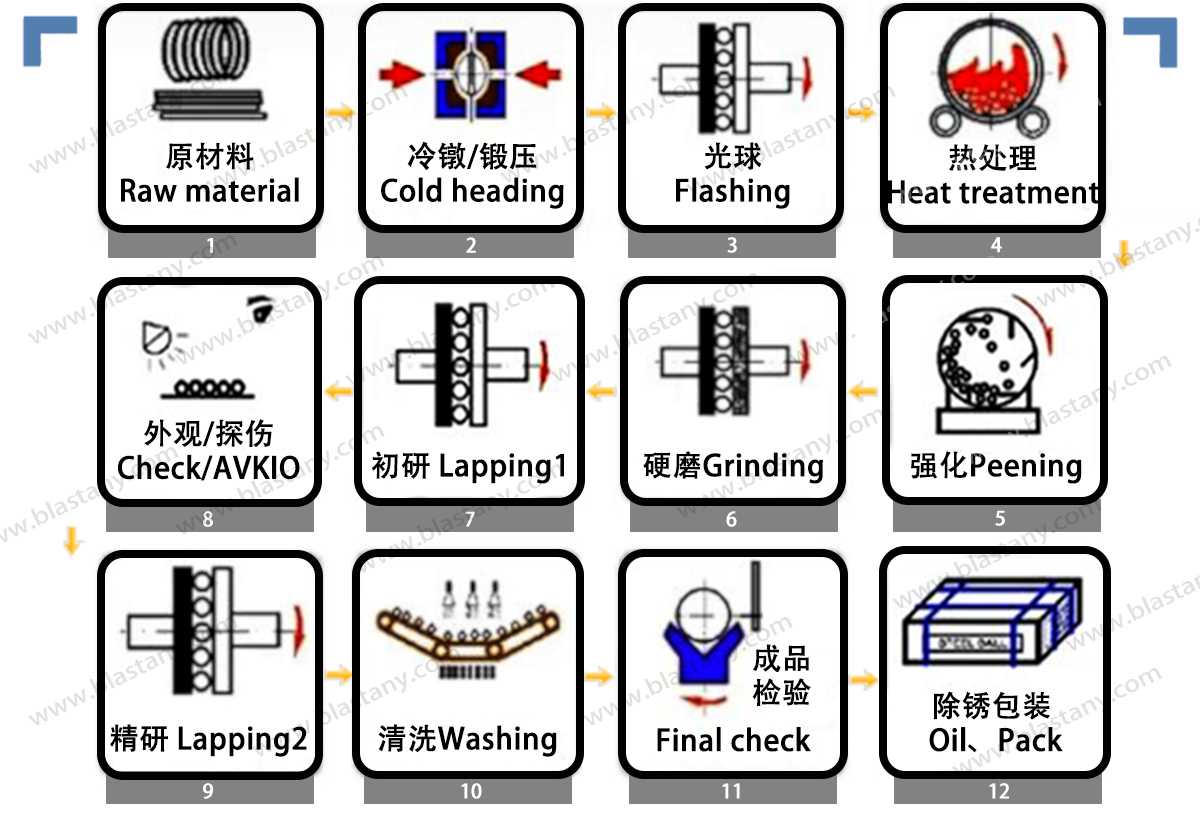

Inkqubo yokuvelisa

Inkqubo yokwenziwa kweMveliso yeeMveliso zeBhola echanekileyo

1.Izinto zoMthetho

Kwizigaba zayo zokuqala, ibhola iqala kwifom yocingo okanye intonga. Ulawulo lomgangatho luhamba ngovavanyo lwe-metallurgic ukuze kuqinisekiswe ukuba ukubunjwa kwezinto kuphakathi koluhlu olwamkelekileyo.

2.Isihloko

Emva kokuba imathiriyeli ekrwada idlulise ukuhlolwa, ithi ke yondliwe ngentloko yesantya esiphezulu. Oku kwenza iibhola ezirhabaxa kakhulu.

3.Ukudanyaza

Inkqubo edanyazayo icoca iibhola ezinentloko ukwenzela ukuba zibe mtyibilizi ngokwembonakalo.

4.Unyango lobushushu

Inkqubo yokushisa ephezulu kakhulu apho iibhola ezikhanyayo zifakwe kwi-oven ye-industrial. Oku kwenza lukhuni ibhola.

5.Ukusila

Ibhola iyangqutywa ukuya kutsho kumlinganiselo oqikelelwayo wesayizi yebhola.

6.Ukuqhwaba

Ukuqhwatywa kwebhola kuyizisa kwinqanaba lokugqibela elinqwenelwayo. Le yinkqubo yokugqibela yokwenza ibhola kwaye ifumana ibhola phakathi kokunyamezelana kwebakala.

7.Uhlolo lokugqibela

Ibhola ke ilinganiswe ngokuchanekileyo kwaye ihlolwe nguLawulo loMgangatho ukuqinisekisa olona mgangatho uphezulu.

Iindidi zeemveliso