Amaso eglasi anezalathisi ze-refractive ze-1.9 kunye ne-2.2

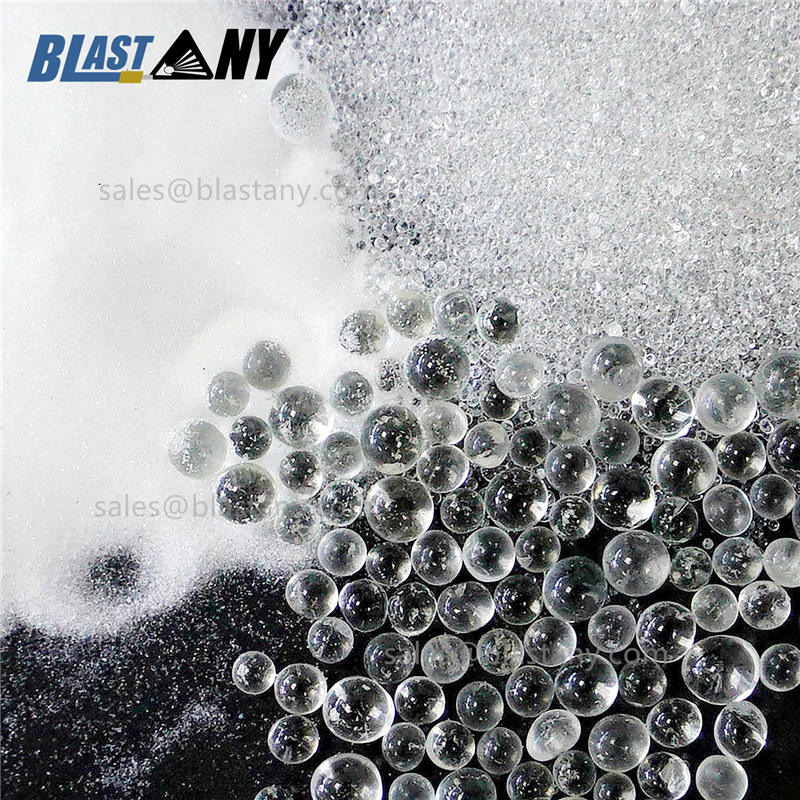

ISandblasting Glass Beads

I-Junda glass bead luhlobo lokuqhushumba kwe-abrasive ukuze kugqitywe umphezulu, ngokukodwa ukulungisa iintsimbi ngokuzigudisa. Ukuqhunyiswa kwamaso kubonelela ngokucocwa okuphezulu komphezulu ukususa ipeyinti, umhlwa kunye nezinye iingubo.

Inkqubo yokuqhushumba kwentsimbi yeglasi ihambelana nokusingqongileyo kwaye ayinazo iikhemikhali kwaye ingasetyenziselwa ukukhangela iziphene ze-weld kunye ne-solder. Izinto ezilungileyo zokusebenzisa i-glass bead blasting ziquka:

●Uluhlu olukhulu lwamabanga akhoyo kwimisebenzi eyahlukeneyo kunye neeprofayili.

●Ayiphazamisi kwiingubo njengoko ingasebenzi.

●Ayishiyi ntsalela okanye izingcolisi ezizinzisiweyo, kwaye ayibangeli naluphi na utshintsho lomphezulu womphezulu.

●Ukuphuculwa kokumelana nomhlwa kunye nokukwazi ukugudisa iziphene zomhlaba.

●Akukho silica yekristale ibonakala.

Ingaba isebenza kanjani?

IJunda Glass blasting kusetyenziswa amaso eglasi acolekileyo anobukhulu obahlukeneyo kumanqanaba ahlukeneyo oxinzelelo. Iingqukuva zeglasi ezincinci zikhokelela kumphezulu ogudileyo ngelixa iingqukuva ezinkulu zivelisa ukugqibezela okwenziwe ngakumbi.

Amaso eglasi ayisusi nayiphi na isiseko sesinyithi okanye ifake umphezulu. Iya kuvelisa ukugqibezela okungcono, okufanayo ngakumbi ngelixa isongeza ukukhanya okanye ukuqaqamba kwindawo.

Ineentlobo ngeentlobo zezicelo, kuquka:

●Ukugqiba: Ingasetyenziswa kuluhlu olubanzi lwezinto, kubandakanya isinyithi, iglasi, iplastiki kunye nerabha.

●Ukucoca: Ngaphandle kokwenza utshintsho lomphezulu we-dimensional, ukuqhushumba kwamaso eglasi kususa/coca izinto zangaphandle.

●I-Deburring: Ukuze kudityaniswe kwaye kusebenze iinxalenye, iikona kunye nemiphetho kunokufuna ukuchithwa. Ukuqhushumba kwentsimbi yeglasi kunokususa iingqushu kunye neencam ezinentsiba ngelixa uqinisekisa ukuba akukho siseko sentsimbi kumphezulu sisusiwe.

●Ukuchama: Ukuchama kwandisa ubomi bamalungu esinyithi ngokulwa neentanda zoxinzelelo kunye nokudleka.

Amaso eglasi okuphawula imiphezulu yendlela

I-Junda Road yokumakisha iglasi yeglasi yenziwe ngesanti yeglasi, inkunkuma yeglasi njengesixhobo esikrwada, emva kokunyibilika kobushushu obuphezulu kwaye yenze amaso eglasi amancinci, phantsi kwemakroskopu njengengqukuva engenambala ebonakalayo, ububanzi phakathi kwe-75 microns ukuya kwi-1400 microns, okwangoku kwimveliso ephambili yendlela yeglasi ebonakalisa amaso yinkqubo yomlilo edadayo.

I-Junda Road yokumakisha amaso eglasi isetyenziswa ikakhulu kuhlobo lobushushu obuqhelekileyo, uhlobo olushushu olunyibilikayo lokumakisha indlela yokumakisha, enye njengezinto ezixutyiweyo, inokuqinisekisa ukumakishwa kwixesha lokuphila lokubonisa, enye kwindawo yokumakisha umphezulu wolwakhiwo, inokudlala isiphumo esibonakalisayo.

Amaso eglasi asetyenziswa njengohlobo lomsebenzi ophezulu, izinto eziphilayo ukuya ngaphandle kwamaso eglasi, ukwenza amaso eglasi abuthathaka, into eyenzeka kumphezulu woluthuli emoyeni, ngenxa yokuba amaso eglasi aqulethe i-agent ethile yokudibanisa, aphucule amaso kunye namandla adibeneyo okwambathisa anokuthintela amaso amancinane eglasi xa edada phezu kwawo. indawo enkulu yomphezulu, inokunyusa izinga lokusetyenziswa elingaphezulu kwe-30%, ngoku amaso eglasi ebonakalisayo abe sisixhobo sokubonisa esingenakuphinda sibuyiselwe kwiimveliso zokhuseleko ezindleleni.

Sinokubonelela ngamaso eglasi ngesalathiso esahlukileyo se-refractive se-1.53, 1.72, 1.93 njalo njalo, sinokubonelela ngamaso eglasi emigangatho eyahlukeneyo yelizwe, okanye ngokuhambelana nobungakanani obubonelelwa ngabathengi.

Sinikezela ngamaso eglasi asezantsi

Umgangatho waseTshayina: GB / T 24722 - 2009 No.1, 2, 3

Umgangatho waseKorea: KSL 2521 No.1 kunye ne-2

Umgangatho waseBritani: BS6088 Udidi A kunye no-B

Umgangatho waseMelika: AASHTO M247 uhlobo 1 kunye nohlobo lwe-2

Umgangatho waseYurophu : EN1423 kunye ne-EN1424

Umgangatho waseTurkey: TS EN1423

Umgangatho waseNew Zealand: NZS2009: 2002

Umgangatho waseTaiwan: CNS

Umgangatho waseJapan: JIS R3301

UmGangatho weOstreliya waseOstreliya : A, B, C, D

UkuSila amaso eglasi

IJunda Ukugaya intsimbi yeglasi luhlobo lwentsimbi yeglasi enobukhulu obufanayo, umphezulu ogudileyo, ubulukhuni obuphezulu kunye nokuzinza okuhle kweekhemikhali. Amaso okusila ngokuqhelekileyo ngamaso eglasi anesayizi yamasuntswana angaphezu kwe-1mm. Azinambala kwaye ziyabonakala ngenkangeleko kwaye ziyi-sphere ecocekileyo. Isetyenziswa ngokubanzi kwidayi, ipeyinti, i-inki, imboni yeekhemikhali kunye nenye i-arhente yokusabalalisa, i-medium medium and filling materials.

Sinokubonelela nge-0.8 1.2, 1.0, 1.5, 1.5, 2.0, 2.0, 2.5, 2.5, 3.0, 3.0, 3.5 mm ubukhulu bezi bambalwa.

Kwakhona ngokweemfuno zabathengi.

Isicelo

1.I-Bead ibetha iindawo zenqwelomoya, phelisa uxinzelelo lwayo, ukomeleza amandla okudinwa, kunye nokunciphisa ukungqubana kunye nokunxiba;

2.Unyango lwe-Anodic kunye ne-electroplating ngaphambi kokucubungula, ngaphezu kokucoca kunokunyusa ukunamathela;

3. Intsimbi yensimbi engenasici yokusebenzela i-welding pass yokucoca kunye nokususwa komkrwelo womphezulu kunye nolunye ulungiso lobuhle;

4. Ukucoca kunye nokuchithwa kwesikhunta sokusika ucingo;

5. ukwehla kokungunda kwerabha;

Iiparamitha zobuGcisa

| Iprojekthi | Umgangatho | |

| Ukwakheka kweekhemikhali% | SiO2 | >72% |

| CaO | >8% | |

| Na2O | <14% | |

| MgO | >2.5% | |

| Al2O3 | 0.5-2.0% | |

| Fe2O3 | 0.15% | |

| Abanye | 2.0% | |

| Refractive Index | N≥1.5% | |

| Ukuxinana | 2.4-2.6g/cm3 | |

| Ukuhanjiswa kobungakanani | Ubukhulu obugqithisileyo ≤5% ngaphantsi kobungakanani ≤10% | |

| Idayamitha yocingo | 0.03-0.4mm | |

| Ukuqina | 3-5 % | |

| Ukuqina | 6-7 MOHS; 46HRC | |

| Ubulukhuni obuncinci | ≥650kg/cm3 | |

| Isetyhula | Ireyithi yomjikelo ≥85% | |

| Imbonakalo | ingenambala, iglasi ebonakalayo ngaphandle kokungcola, iRound kwaye igudileyo | |

| Isicelo | 1.Ukugaya 2.Ipeyinti yophawu lwendlela 3.Ukuqhushumba kwesanti | |

| Umxholo okhokelayo | Akukho mxholo okhokelayo, fikelela kwi-American 16CFR 1303 umgangatho womxholo okhokelayo | |

| Umxholo wezinto ezinobungozi | Ngaphantsi kwe-American 16CFR 1500 standard | |

| Uvavanyo oluvuthayo lomlilo | Akukho ukuvutha lula, ukufikelela American 16CFR 1500.44 umgangatho | |

| Umxholo wentsimbi enzima enyibilikayo | Umxholo wesinyithi womlinganiselo we-soluble matter ratio umlinganiselo wobunzima obuqinileyo awukho ngaphezu kwe-ASTM F963 ixabiso elihambelanayo | |

| Iphakheji | ||

| Uhlobo | Umnatha | IMicronsm Max(μm) | IMicrons Min(μm) |

| 30# | 20-40 | 850 | 425 |

| 40# | 30-40 | 600 | 425 |

| 60# | 40-60 | 425 | 300 |

| 80# | 60-100 | 300 | 150 |

| 100# | 70-140 | 212 | 106 |

| 120# | 100-140 | 150 | 106 |

| 150# | 100-200 | 150 | 75 |

| 180# | 140-200 | 106 | 75 |

| 220# | 140-270 | 106 | 53 |

| 280# | 200-325 | 75 | 45 |

| 320# | >325 | 45 | 25 |

Iindidi zeemveliso