Abathengisi abalungileyo beZirconia zokuSila amaso eMedia, iYttrium ezinzisiweyo iiBhola zokuSila iZirconium Oxide

Sihlala sikholelwa ukuba umlingiswa womntu uthatha isigqibo somgangatho ophezulu wemveliso, iinkcukacha zithatha isigqibo somgangatho ophezulu wemveliso, kunye ne-RELISTIC, OKUSEBENZAYO KUNYE NE-INNOVATIVE crew umoya kubathengisi abalungileyo beZirconia Zokugaya iMedia Beads, i-Yttrium Stabilized Zirconium Oxide Grinding Balls, Umbuzo wakho uya kwamkeleka kakhulu kwaye silindele ukuba siphumelele.

Sihlala sikholelwa ukuba umlingiswa womntu uthatha isigqibo somgangatho ophezulu weemveliso, iinkcukacha zithatha isigqibo somgangatho ophezulu wemveliso, kunye ne-REALISTIC, OKUFANELEKILEYO kunye nomoya we-INNOVATIVE crew.Iibhola zokuSila zaseTshayina kunye neNano Ball Mill, Kukwaneliseka kwabathengi bethu malunga nezinto esizithengisayo kunye neenkonzo ezihlala zisikhuthaza ukuba senze ngcono kweli shishini. Sakha ubudlelwane obunenzuzo ngokufanayo kunye nabathengi bethu ngokubanika ukhetho olukhulu lwamalungu emoto yeprimiyamu ngamaxabiso aphawulweyo. Sinikezela ngamaxabiso athengiswayo kuwo onke amacandelo ethu asemgangathweni ukuze uqinisekiswe ukonga okukhulu.

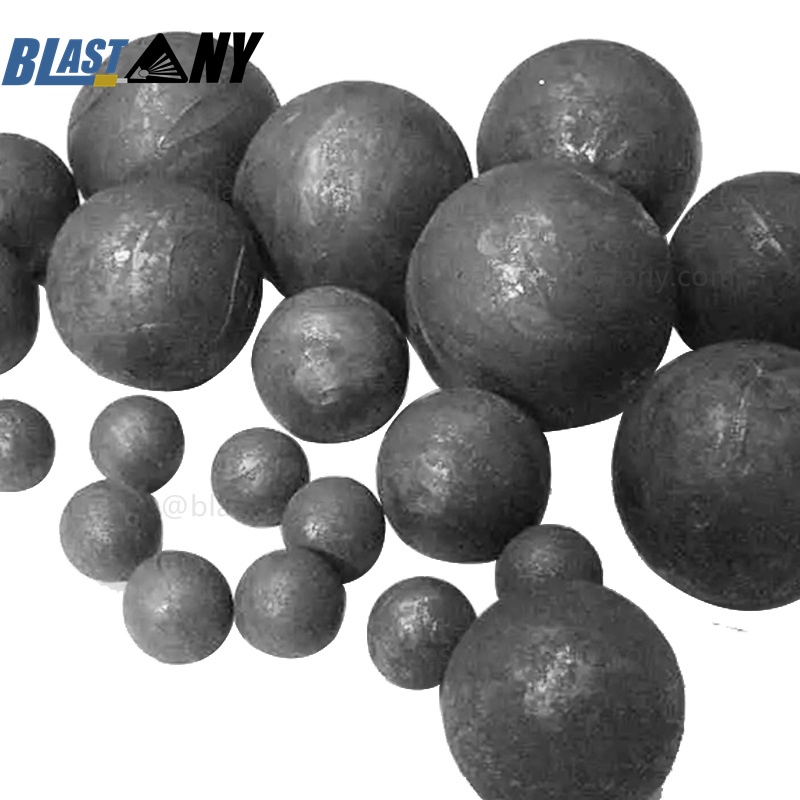

Inkqubo yokuvelisa

Emva kokujonga kunye nokuvavanya izinto ezijikelezileyo zentsimbi yentsimbi, imveliso inokuqaliswa ngokobungakanani bebhola yentsimbi. I-forging yensimbi ifudunyezwa kwiqondo lokushisa elithile ngokudibanisa ne-furnace frequency ukuqinisekisa ukuveliswa okusebenzayo kwezinto eziguquguqukayo kwi-forging; I-red-hot steel forging ithunyelwa kwihamile yomoya kwaye iqhutywe ngabaqhubi abanezakhono. Emva kokubumba ibhola yentsimbi ebomvu eshushu ngokukhawuleza kwi-JUNDA eyenzelwe ngokukhethekileyo izixhobo zonyango lobushushu lokucima kunye nokunyangwa kobushushu, ixabiso eliphezulu kunye nobunzima obufanayo bebhola yentsimbi linokuqinisekiswa.

Uphawu

1.Ukuqina kwempembelelo ephezulu

2.Intlangano ehlangeneyo

3.Ukumelana nokunxiba okuphezulu

4.Izinga lokuqhawula eliphantsi

5.Ubunzima obufanayo

6.Akukho deformation

Ukupakisha kunye noThutho

| Isingxobo sesingxobo | Igubu lentsimbi | |

| Ubunzima beNet 1000kgs kuzo zonke iibhola ezinobungakanani | Ubungakanani bebhola | Ukusinda okushiyekile |

| 20-30mm | 930-1000KGS | |

| 40-60mm | 900-930KGS | |

| 70-90mm | 830-880KGS | |

| 100mm nangaphezulu | 830-850KGS | |

| Ingxowa: 73×60cm, 1.5KG, 0.252CBMDrum: 60×90cm, 15-20KG, 0.25CBMPallet eyodwa: 60×60×9cm, 4-6KG: Kabini: 120×60×10cm, 12-14KG | ||

Phawula

Uchungechunge lwe-1.JD SG4-4 sisixhobo esikhethekileyo esixhasayo kwi-JD yoxinzelelo lwe-sandblasting machine.

2. Lungisa iqondo lokuxinana kwelungu langaphandle linokuthi ngendlela ethile lilungelelanise isantya sokusonta sesibambi somlomo osontayo. Kwaye isantya kufuneka silawulwe ngaphakathi kwe-30 ~ 500r / min.

3.Ukuba isibambi somlomo we-nozzle siyeka ukujikeleza okanye ukusonta ngokucothayo, inokuba kungenxa yoxinzelelo, ijoyini yangaphandle exinene kakhulu, iibheringi ezibambekileyo okanye umbhobho oxineneyo. Misa umatshini, uze ulungelelanise kwaye ukhangele.

4. Phambi kokuba usebenze, umbhobho okwisanti yesanti kufuneka ufakwe eludongeni ukusuka kwelinye icala ukuya kwelinye, kwaye umoya ocinezelweyo owomileyo kufuneka ungene. Xa usebenza, umbhobho oqhushumbayo kufuneka utsalwe ngaphandle kancinci ukuze uphume ngesantya esingaguqukiyo. Ukuba umgangatho wokucoca awukwazi ukuhlangabezana neemfuno, phinda usebenze ukuze ufumane umphumo owanelisayo.

5.Ukuba i-abrasives ivaliwe kwaye ayikwazi ukutshizwa, kufuneka ivalwe kuqala kwaye ikhuphe, emva koko ube nesheke. 6). Iindawo ezinxiba ngokukhawuleza kufuneka zihlolwe rhoqo, kufuneka zitshintshwe ngexesha elifanelekileyo ukuba zinxibile, okanye ziya kuba nefuthe elibi ekusebenzeni kakuhle kunye nomgangatho wokuqhushumba, kwaye mhlawumbi i-Exhaust izisa iingozi.

Imilinganiselo yobugcisa

| Iimpawu zobuchwephesha bokubumba ibhola yensimbi | ||||||||||||

| Intshi | Ubungakanani | T ubunzima | Ukunyamezela(mm) | Izinto eziphathekayo | Ukuqina komphezulu (HRC) | Ubunzima bomthamo(HRC) | ||||||

| 3/4″ | D20mm | 0.037+/-0.005 | 2+/-1 | B2 | 63-66 | 63-66 | ||||||

| 1″ | D25mm | 0.072+/-0.01 | 2+/-1 | B2 | 63-66 | 63-66 | ||||||

| 11/4″ | D30mm | 0.13+/-0.02 | 2+/-1 | B2 | 63-66 | 63-66 | ||||||

| 11/2″ | D40mm | 0.30+/-0.04 | 2+/-1 | B2 | 62-66 | 62-66 | ||||||

| 2″ | D50mm | 0.6+/-0.05 | 2+/-1 | B2 | 62-65 | 61-64 | ||||||

| 21/2″ | D60mm | 1.0+/-0.05 | 2+/-1.5 | B2 | 62-65 | 60-62 | ||||||

| 21/2″ | D65mm | 1.3+/-0.05 | 2+/-1.5 | B2 | 61-64 | 60-62 | ||||||

| 21/2″ | D65mm | 1.3+/-0.05 | 2+/-1.5 | B3 | 61-63 | 60-62 | ||||||

| 3″ | D75mm | 2.0+/-0.06 | 3+/-2 | B3 | 61-63 | 60-62 | ||||||

| 3″ (Ishushu isongwe) | D80mm | 2.0+/-0.06 | 3+/-2 | B3 | 60-63 | 60-62 | ||||||

| 3″(Yenziwe) | D80mm | 2.1+/-0.06 | 3+/-2 | B3 | 60-62 | 53-57 | ||||||

| 31/2″ | D90mm | 3.0+/-0.07 | 3+/-2 | B3 | 60-63 | 59-62 | ||||||

| 4″ | D100mm | 4.1+/-0.15 | 3+/-2 | B3 | 60-63 | 59-62 | ||||||

| 4.5″ | D115mm | 6.3+/-0.15 | 3+/-2 | B3 | 60-63 | 57-60 | ||||||

| 5″ | D125mm | 8.1+/-0.3 | 3+/-2 | B3 | 59-62 | 55-60 | ||||||

| Ukwakhiwa kweekhemikhali | C% | Si% | Mn% | Cr% | P% | S% | Ni% | |||||

| B2 | 0.72-1.03 | 0.15-0.35 | 0.3-1.2 | 0.2-0.6 | ≤0.035 | ≤0.035 | I≤0.25 | |||||

| B3 | 0.53-0.88 | 1.2-2.00 | 0.50-1.20 | 0.7-1.20 | ≤0.035 | ≤0.035 | I≤0.25 | |||||

Sihlala sikholelwa ukuba umlingiswa womntu uthatha isigqibo somgangatho ophezulu wemveliso, iinkcukacha zithatha isigqibo somgangatho ophezulu wemveliso, kunye ne-RELISTIC, OKUSEBENZAYO KUNYE NE-INNOVATIVE crew umoya kubathengisi abalungileyo beZirconia Zokugaya iMedia Beads, i-Yttrium Stabilized Zirconium Oxide Grinding Balls, Umbuzo wakho uya kwamkeleka kakhulu kwaye silindele ukuba siphumelele.

Sihlala sikholelwa ukuba umlingiswa womntu uthatha isigqibo somgangatho ophezulu wemveliso, iinkcukacha zithatha isigqibo somgangatho ophezulu wemveliso, kunye ne-RELISTIC, OKUSEBENZAYO KUNYE NE-INNOVATIVE crew umoya kubathengisi abalungileyo beZirconia Zokugaya iMedia Beads, i-Yttrium Stabilized Zirconium Oxide Grinding Balls, Umbuzo wakho uya kwamkeleka kakhulu kwaye silindele ukuba siphumelele.

Abathengisi abalungileyoIibhola zokuSila zaseTshayina kunye neNano Ball Mill, Kukwaneliseka kwabathengi bethu malunga nezinto esizithengisayo kunye neenkonzo ezihlala zisikhuthaza ukuba senze ngcono kweli shishini. Sakha ubudlelwane obunenzuzo ngokufanayo kunye nabathengi bethu ngokubanika ukhetho olukhulu lwamalungu emoto yeprimiyamu ngamaxabiso aphawulweyo. Sinikezela ngamaxabiso athengiswayo kuwo onke amacandelo ethu asemgangathweni ukuze uqinisekiswe ukonga okukhulu.

Iindidi zeemveliso