Umgangatho ophezulu owenziwe ngentsimbi ekhatywayo enokumelana nokunxiba okuphezulu

Yazisa

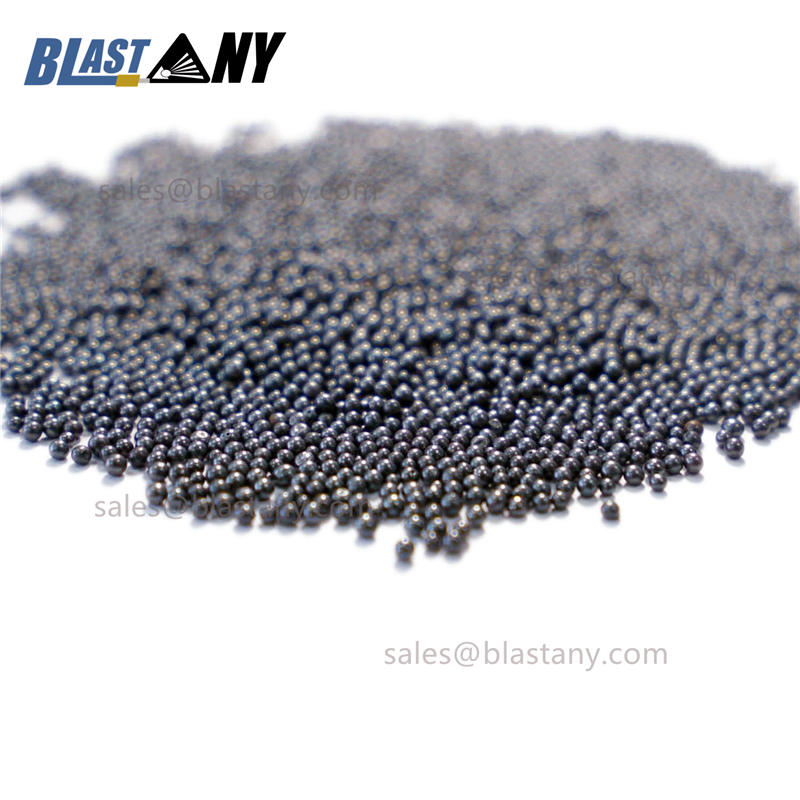

I-Junda Steel Shot yenziwe ngokunyibilikisa i-scrap ekhethiweyo kwiziko lokufakelwa kombane. Ukwakhiwa kweekhemikhali zentsimbi etyhidiweyo ihlalutywa kwaye ilawulwa ngokungqongqo nge-spectrometer ukufumana inkcazo yoMgangatho we-SAE. Intsimbi etyhidiweyo i-atom kwaye iguqulwa ibe yincinci ejikelezayo kwaye emva koko icinywe kwaye igxininiswe kwinkqubo yokushisa ukushisa ukuze ifumane imveliso yobunzima obufanayo kunye ne-microstructure, ihlolwe ngobukhulu ngokuhambelana nomgangatho we-SAE.

Junda industrial shot intsimbi yahlulwe zibe ezine, umgangatho wesizwe ukudubula intsimbi, equlathe chromium cast steel shot, iipilisi carbon steel ephantsi, intsimbi stainless, kubandakanywa umgangatho wesizwe udubulo intsimbi ukuphoswa ngokupheleleyo ngokungqinelana neemfuno umgangatho wesizwe isiqulatho isiqulatho kwimveliso, kunye element of chromium cast intsimbi shot, isekelwe kumgangatho wesizwe iibhola zentsimbi, ukongeza ferromanganese ezifana inkqubo ferrowenmel ephilayo, izinto ezinde ferrowen ; Inkqubo yokuvelisa i-carbon steel shot ephantsi kunye ne-standard steel shot shot, kodwa izinto eziluhlaza ziphantsi kwe-carbon steel, umxholo wekhabhoni uphantsi; I-shot steel stainless iveliswa yinkqubo yokwenza i-atomizing, izinto eziluhlaza ziyinsimbi engenasici, i-304, i-430 yensimbi engenasici njalo njalo.

Olu hlobo lokudubula lwenzelwe ukusetyenziswa kwiinkqubo zokuqhushumba kunye nokuqhushumba phantsi koxinzelelo lomoya oxinanisiweyo. Ngokusisiseko isetyenziswa kwiintsimbi ezingezizo i-ferrous ezifana ne-aluminiyam, i-zinc alloys, iintsimbi ezingenasici, ubhedu, ubhedu, ubhedu...

Ngoluhlu lwayo olubanzi lokuhlelwa, isetyenziselwa ukucoca, ukuchithwa, ukuxinzelela, ukudubula ukuchama kunye neenkqubo zokugqiba ngokubanzi, kuzo zonke iintlobo zamalungu, ngaphandle kokungcolisa umphezulu wayo ngothuli lwe-ferrous oluwohlokayo kunye nokutshintsha umbala wesinyithi esicociweyo. kwinkqubo yokuguga yemarble kunye negranite.

Ukusetyenziswa kweshishini

Ukudubula kwentsimbi

Isitofu sentsimbi sicoca isanti egayiweyo kunye nesanti etshisiweyo -kwisanti yokugalela ukwenza umphezulu ufumane ukucoceka okulungileyo kunye noburhabaxa obufunekayo, ukuze kube luncedo ekuqhubeni nasekugqumeni.

Ukudubula kwentsimbi yokulungiselela umphezulu wepleyiti yentsimbi

Ukudubula kwentsimbi yokucoca ulusu lweoxide, umhlwa kunye nokunye ukungcola ngokudutyulwa Ukudubula, emva koko usebenzisa isicoci sevacuum okanye umoya ocociweyo ocociweyo ukucoca umphezulu wemveliso yentsimbi.

Izithonga zentsimbi ezisetyenziselwa oomatshini bobuNjineli

Izithonga zentsimbi ezisetyenziselwa ukucoca oomatshini zinokususa ngokufanelekileyo umhlwa, i-welding slag, kunye nolusu lwe-oxide, ziphelise uxinzelelo lwe-welding, kwaye zonyuse amandla okubopha okusisiseko phakathi kokususa umhlwa kunye nentsimbi, ngaloo ndlela iphucula kakhulu umgangatho wobunjineli bobunjineli obusecaleni.

Ubungakanani bokudubula kwentsimbi yokucoca ipleyiti yentsimbi

Ukuze kuphunyezwe ukucoceka okucocekileyo, okukhanyayo, okugqwesileyo kunyango lomphezulu wepleyiti yentsimbi, kufuneka kukhethwe izinto ezifanelekileyo zokurhaxa ukususa isikali kumphezulu wentsimbi eqengqelekayo.

Ngokwamanqanaba ahlukeneyo, umphezulu wentsimbi engenasici kufuneka ukhethe iibrasives ezahlukeneyo zedayamitha kunye nomlinganiselo wokusetyenzwa. Xa kuthelekiswa nenkqubo yeekhemikhali zendabuko, inokunciphisa iindleko zokucoca kunye nokufezekisa imveliso eluhlaza.

Steel shot blast media for Pipeline anti-corrosion

Imibhobho yentsimbi idinga unyango olungaphezulu ukwenzela ukuqinisa ukuxhatshazwa kwe-corrosion. Ngokudutyulwa kwentsimbi, ukugqabhuza iipolishe zeendaba, ukucoca nokususa ioksidi kunye nezincamatheliso zifezekisa umhlwa oceliweyo wokususa ubunzulu kunye nobunzulu obuziinkozo, kungekuphela nje ukucoca umphezulu kodwa nokwanelisa ukuncamathela phakathi kombhobho wentsimbi kunye nokwaleka, ukuphumeza isiphumo esihle sokuchasa umhlwa.

Steel shot peening ukomeleza

Amalungu esinyithi asebenza kwimeko yokulayisha i-cyclic kwaye aphantsi kwesenzo soxinzelelo lwebhayisikile kufuneka adutyulwe inkqubo yokomeleza i-peening ukuphucula ubomi bokudinwa.

Cast steel shot domains Isicelo

Intsimbi yentsimbi yokukrola isetyenziswa ikakhulu ekomelezeni ukusetyenzwa kweendawo ezibalulekileyo ezifana nentwasahlobo ye-helical, intwasahlobo yeqabunga, ibha ejijekileyo, igiya, iindawo zokuhambisa, ukuthwala, i-cam shaft, i-asi egobileyo, intonga yokudibanisa njalo njalo. Xa inqwelomoya isima, isixhobo sokumisa kufuneka simelane nempembelelo eyoyikekayo efuna unyango lokuchama rhoqo. Amaphiko nawo afuna unyango lokukhululwa koxinzelelo lwexesha.

Iiparamitha zobuGcisa

| Iprojekthi | ImiGangatho yeSizwe | Umgangatho | |

| Ukwakheka kweekhemikhali% | C | 0.85-1.20 | 0.85-1.0 |

| Si | 0.40-1.20 | 0.70-1.0 | |

| Mn | 0.60-1.20 | 0.75-1.0 | |

| S | <0.05 | <0.030 | |

| P | <0.05 | <0.030 | |

| Ukuqina | shot yentsimbi | HRC40-50 HRC55-62 | HRC44-48 HRC58-62 |

| Ukuxinana | shot yentsimbi | ≥7.20 g/cm3 | 7.4g/cm3 |

| Microstructure | I-Tempered Martensite okanye iTroostite | Umbutho we-Tempered Martensite Bainite Composite | |

| Imbonakalo | I-Spherical Amasuntswana angumngxuma <10% Iqhekeza leqhekeza <15% | I-Spherical Amasuntswana angumngxuma <5% Iqhekeza leqhekeza <10% | |

| Uhlobo | S70, S110, S170, S230, S280, S330, S390, S460, S550, S660, S780 | ||

| Ukupakisha | Itoni nganye kwiPallet eyahlukileyo kunye netoni nganye yahlulwe kwiipakethi ze-25KG. | ||

| Ukuqina | 2500 ~ 2800 amaxesha | ||

| Ukuxinana | 7.4g/cm3 | ||

| Ububanzi | 0.2mm, 0.3mm, 0.5mm, 0.6mm, 0.8mm, 1.0mm, 1.2mm, 1.4mm, 1.7mm, 2.0mm, 2.5mm | ||

| Usetyenziso | 1. Ukucoca uqhushumbo: Isetyenziselwa ukucocwa koqhushumbo lokuphosa, ukuphosa, ukuphosa; ukususwa kwesanti yokuphosa, ipleyiti yensimbi, i-H yodidi lwentsimbi, isakhiwo sentsimbi. 2. Ukususwa kwe-rust: Ukususwa kwe-rust of casting, forging, ipleyiti yensimbi, uhlobo lwe-H yensimbi, isakhiwo sensimbi. 3. Shot peening: Shot peening of gear, iindawo eziphathwe ubushushu. 4. Ukudubula ukudubula: Ukudubula kwentsimbi yeprofayili, ibhodi yeenqanawa, ibhodi yentsimbi, izinto zentsimbi, isakhiwo sentsimbi. 5. Unyango lwangaphambili: Ukulungiswa kwangaphambili kwendawo, ibhodi yensimbi, iprofayili yensimbi, isakhiwo sensimbi, ngaphambi kokupenda okanye ukugqoka. | ||

Ubungakanani Ukusasazwa Of Steel Shot

| SAE J444 Standard Steel shot | Inombolo yesikrini. | In | Ubungakanani bekhusi | |||||||||||

| S930 | S780 | S660 | S550 | S460 | S390 | S330 | S280 | S230 | S170 | S110 | S70 | |||

| BONKE bapasile | 6 | 0.132 | 3.35 | |||||||||||

| Phasa konke | 7 | 0.111 | 2.8 | |||||||||||

| 90% imizuzu | Phasa konke | 8 | 0.0937 | 2.36 | ||||||||||

| 97% min | 85% min | Phasa konke | Phasa konke | 10 | 0.0787 | 2 | ||||||||

| 97% min | 85% min | 5% max | Phasa konke | 12 | 0.0661 | 1.7 | ||||||||

| 97% min | 85% min | 5% max | Phasa konke | 14 | 0.0555 | 1.4 | ||||||||

| 97% min | 85% min | 5% max | Phasa konke | 16 | 0.0469 | 1.18 | ||||||||

| 96% min | 85% min | 5% max | Phasa konke | 18 | 0.0394 | 1 | ||||||||

| 96% min | 85% min | 10% max | Phasa konke | 20 | 0.0331 | 0.85 | ||||||||

| 96% min | 85% min | 10% max | 25 | 0.028 | 0.71 | |||||||||

| 96% min | 85% min | Phasa konke | 30 | 0.023 | 0.6 | |||||||||

| 97% min | 10% max | 35 | 0.0197 | 0.5 | ||||||||||

| 85% min | Phasa konke | 40 | 0.0165 | 0.425 | ||||||||||

| 97% min | 10% max | 45 | 0.0138 | 0.355 | ||||||||||

| 85% min | 50 | 0.0117 | 0.3 | |||||||||||

| 90% min | 85% min | 80 | 0.007 | 0.18 | ||||||||||

| 90% min | 120 | 0.0049 | 0.125 | |||||||||||

| 200 | 0.0029 | 0.075 | ||||||||||||

| 2.8 | 2.5 | 2 | 1.7 | 1.4 | 1.2 | 1 | 0.8 | 0.6 | 0.4 | 0.3 | 0.2 | GB | ||

Amanyathelo eMveliso

Impahla engekasilwa

Ukubumba

Ukomisa

Uvavanyo

Ukukhetha

Ukufudumeza

Uvavanyo

Iphakheji

Iindidi zeemveliso