Iibhola zensimbi zokusila ziyimithombo yokugaya kunye neyona nto iphambili yebhola yebhola. Zinokuchaphazela ngokuthe ngqo ukusebenza kakuhle kokusila kweplanti yokucoca intsimbi ekrwada kunye nomgangatho wokugqibela wemveliso.

Ngexesha lokugaya, iibhola zentsimbi zokugaya zisetyenziselwa ukuxuba kunye nezinto zokugaya (ezifana neeminerali, iipeyinti, kunye neekhemikhali) zibe ngumgubo ocolekileyo.

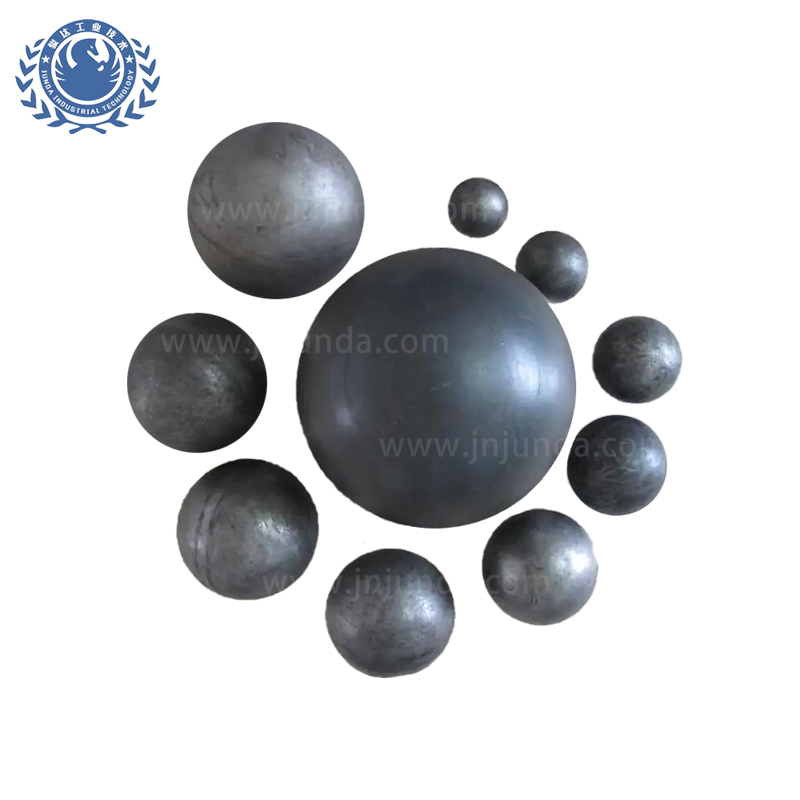

Iintlobo zeebhola zentsimbi zokugaya

Njengoko iibhola zentsimbi zokusila zifuna ukuxhathisa okulungileyo kwe-abrasion kunye nokuqina kwempembelelo eyaneleyo, kwaye ayinakuphulwa, i-Fote Machinery yenze uvavanyo lobulukhuni, ukuhlolwa kokwakheka kweekhemikhali kunye nokuhlolwa komgangatho wangaphakathi kwibhola nganye.

Ngokwenkqubo yokuvelisa, iibhola zensimbi zensimbi zokugaya zihlulwe zibe ziibhola zentsimbi ezibunjiweyo kunye nokuphosa iibhola zetsimbi zokugaya.

1. Iibhola zentsimbi zokusila ezibunjiweyo

Ngaba ufuna ukusebenza kakuhle kokusila? Ezemigodi yegolide okanye kwishishini lesamente? Emva koko unokukhetha iibhola zetsimbi zokugaya, ezifumaneka kuzo zonke izigaba zokugaya.

Ibhola yensimbi eyenziwe ngeFote inokohlulwa ibe yikhabhoni ephantsi, ikhabhoni ephakathi, ibhola yentsimbi ephezulu yekhabhoni esekwe kwipesenti yecarbon.

Umxholo wekhabhoni ungaphantsi kwe-1.0%. Umxholo wechromium yi-0.1%-0.5% (Ngokuphangaleleyo ayiqulathanga chromium).

2. Phosa iibhola zentsimbi zokugaya

Njengolunye uhlobo lwemidiya yokugaya, iibhola zensimbi ezigayiweyo zinokubonelela nge-Cr (1% -28%), ubunzima (HRC40-66), kunye ne-Diameter (10mm-150mm) i-alloy cast iron balls.

Zinokwahlulwa zibe yi-chromium ephantsi, i-chromium ephakathi, i-chromium ephezulu, ibhola yokugaya i-chromium ephezulu (CR12% -28%).

Iibhola zentsimbi zokusila zeFote zinaMANDLA AMABINI:

Umlinganiselo ophantsi wokutyumza: Ukuchasana ne-flaking kunye nokutyumza ngamaxesha angama-10 kunezinye iibhola ezenziweyo. Inani leempembelelo zeebhola eziwayo linokufikelela ngaphezulu kwamaxesha angama-100,000. Izinga lokwenyani lokutyumza lingaphantsi kwe-0.5%, kufutshane nokungabikho kokutyumza.

Ukugqitywa kakuhle komphezulu: Umphezulu webhola awuvumelekanga ukuba ube neziphene zokuphosa, ezifana nokuqhekeka, ii-pores ezicacileyo, ukufakwa, imingxuma eyanciphayo, i-insulation ebandayo, isikhumba sendlovu, njl.

Forged VS Cast iibhola zentsimbi zokusila

Iintlobo ezimbini zeebhola zetsimbi zokugaya zinedigri ehlukeneyo yokunxiba, njengoko zicutshungulwa yibhola yensimbi ye-Forged yokusila: Ukucinywa kwamanzi kudla ngokusetyenziselwa ukwenza iibhola zetsimbi, ngoko ke izinga layo eliphukile liphezulu.

Ibhola yentsimbi yokusila: Yamkela ukucinywa kobushushu obuphezulu kunye nonyango olushushu ukwenza iibhola zokusila zibenzima kwaye zingakwazi ukunxiba.

Ke ngoko, uthelekiso lokumelana nokunxiba luboniswe ngezantsi:

Phosa iibhola zentsimbi zokusila > iibhola zentsimbi ezibunjiweyo. Kwaye phakathi kweebhola zentsimbi ephosiweyo, ibhola ephezulu yechromium> ibhola ephakathi yechromium> ibhola yechromium ephantsi.

Ixesha lokuposa: Jan-17-2024