Amaso eglasi abonisa “ubuhlobo bokumphezulu” omkhulu xa kuthelekiswa nezinye izinto ezininzi zokuqhomfa, ezifana ne-alumina, i-silicon carbide, kunye negrit yentsimbi. Olu phawu lubalelwa ikakhulu kwiimpawu zalo zomzimba kunye neekhemikhali ezahlukeneyo. Ubulunga obuphezulu beglasi bubonakaliswa ngokukwazi ukucoca okanye ukupolisha iindawo ngokufanelekileyo ngelixa unciphisa umonakalo kumsebenzi womsebenzi ngokwawo.

Oku kulandelayo zizinto ezininzi eziphambili ezinegalelo kwesi siganeko:

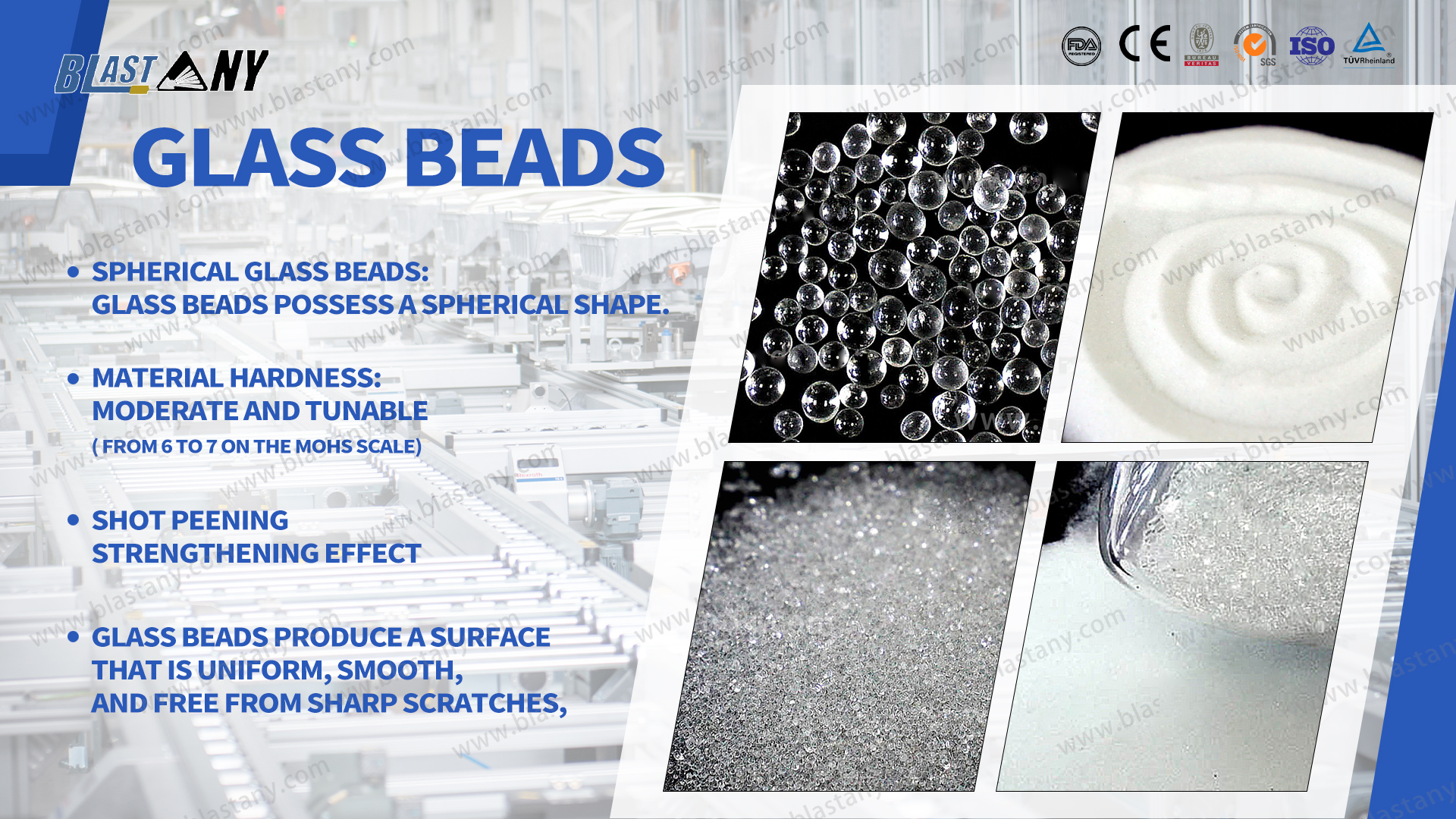

1.Imilo kunye neSakhiwo: I-Spherical vs. Angular

- Amaso eglasi eSpherical: Amaso eglasi anemilo engqukuva. Ngexesha lenkqubo ye-sandblasting kwi-workpiece surfaces, baseka uqhagamshelwano lwamanqaku. Le ndlela yoqhagamshelwano ikhokelela kuxinzelelo oluphantsi. Isenzo sifana ngakumbi nesiphumo "sokucofa" okanye "sokuqengqeleka", ikakhulu sisebenza ukususa izinto ezingcolisa umphezulu, ezinje ngomaleko womhlwa kunye neefilimu zepeyinti ezindala, ngaphandle kokungena nzulu kwizinto zokusebenza.

- Ii-Angular Abrasives: Ngokwahlukileyo, iibrasives ezifana ne-brown corundum, igrit yentsimbi, kunye ne-copper slag ngokuqhelekileyo ibonisa imiphetho ebukhali kunye nengaqhelekanga. Xa zisetyenziselwa ukuqhushumba kwesanti, zenza uqhagamshelwano lwelayini okanye indawo, nto leyo eyenza uxinzelelo olukhulu lwasekuhlaleni. Oku kufana neetshizili ezininzi ezincinci ezikrola umphezulu.

Ubume obungqukuva bamaso eglasi kuthintela ngokufanelekileyo ukusika kunye nokugawulwa okubangelwa yimiphetho ebukhali, ngaloo ndlela kuncitshiswe ngokubonakalayo ukunxitywa kwezinto zokusebenza kunye nokunciphisa ukwanda koburhabaxa bomphezulu.

2.Ubulukhuni beMaterial: Ubuphakathi kunye neTunable

Ubulukhuni beglasi ngokuqhelekileyo buqala ukusuka kwi-6 ukuya kwi-7 kwisikali se-Mohs. Eli nqanaba lobunzima lanele ukususa ngokufanelekileyo ukungcola okuqhelekileyo kwendawo, njengokugqwala (kunye nobunzima be-Mohs be-4 - 5) kunye neefilimu zepeyinti ezindala. Ngaxeshanye, ingaphantsi okanye ithelekiseka nobulukhuni bezinto ezininzi zetsimbi.

3. I-Shot Peening Effect eyomelezayo

Iimpembelelo ezingqukuva zamaso eglasi kumphezulu wentsimbi zenza umaleko woxinzelelo olinganayo kunye nomzuzu. Olu luhlu lubonelela ngeenzuzo ezininzi:

- Ukuchasana nokuFatigue okuphuculweyo: Kuphucula amandla okukhathala kwamacandelo esinyithi, ukuchasana ngokufanelekileyo nokuqaliswa kunye nokusasazwa kweentanda.

-Ingozi yokuNcitshiswa kweStress kuMngcipheko: Umaleko woxinzelelo olucinezelayo wehlisa ukubakho koxinzelelo lwe-corrosion.

- Ukuphuculwa kokumelana nokuNxitywa: Ngokunyanzelisa umsebenzi obandayo owenziwe lukhuni kumphezulu, uphucula ukuxhathisa kokunxiba.

4. Umphezulu wokuGqibela

Ngenxa yobume bawo obungqukuva kunye neempawu zempembelelo, amaso eglasi avelisa umphezulu ofanayo, ogudileyo, ongenawo umkrwelo obukhali, odla ngokubizwa ngokuba "yi-satin finish". Oku kugqitywa kubonelela nge-substrate efanelekileyo yokutshiza okulandelayo, ukugquma, okanye iinkqubo ze-electroplating, ukuqinisekisa ukunamathela okuqinileyo.

Ngokuchaseneyo, ii-abrasives ze-angular zenza i-topography yomhlaba erhabaxa enencopho kunye neentlambo. Ngelixa oku kunokonyusa ukuncamathela ukuya kuthi ga kumlinganiselo othile, kusebenzisa imathiriyeli yokugquma ngakumbi kwaye kukhokelela kwinkangeleko engaphantsi kobuhle bomgangatho ophezulu.

Ngokubhekiselele kwezi nzuzo, iintsimbi zeglasi zisetyenziswa rhoqo kwizicelo apho ukunyaniseka kwe-substrate kubaluleke kakhulu, njengokucutshungulwa kwamacandelo achanekileyo, i-molds, i-aerospace components, iimveliso zensimbi ezingenasici, kunye ne-aluminium alloy die-castings. Bamele ukhetho olufanelekileyo lokuphumeza ukulingana phakathi kokucocwa komphezulu osebenzayo kunye nokukhuselwa kwe-substrate.

Ngolwazi oluthe kratya, nceda uzive ukhululekile ukuxoxa nenkampani yethu!

Ixesha lokuposa: Sep-18-2025