Igrit yentsimbi enemigangatho yeSAE

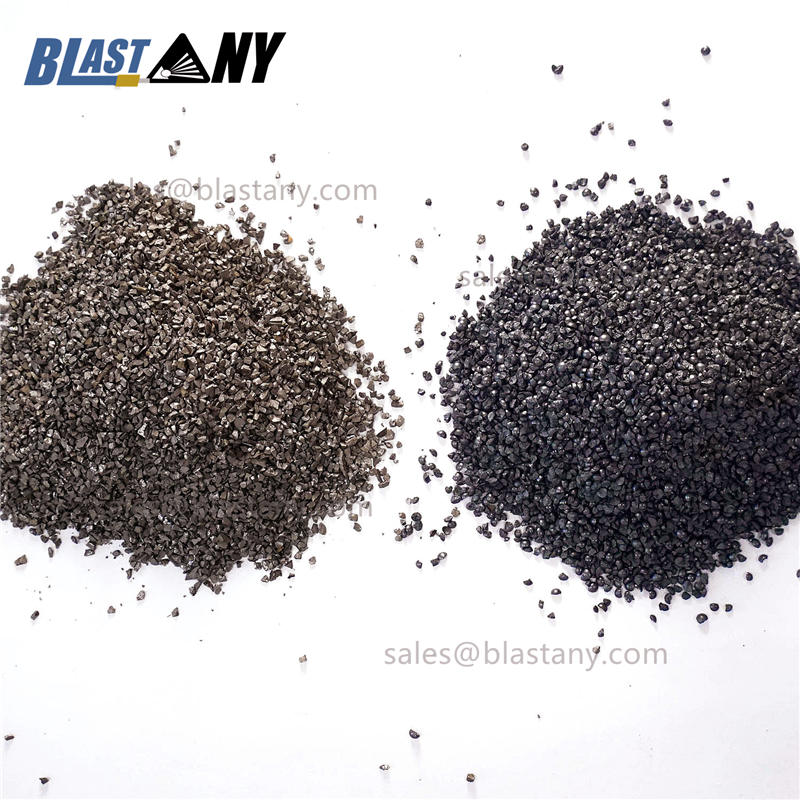

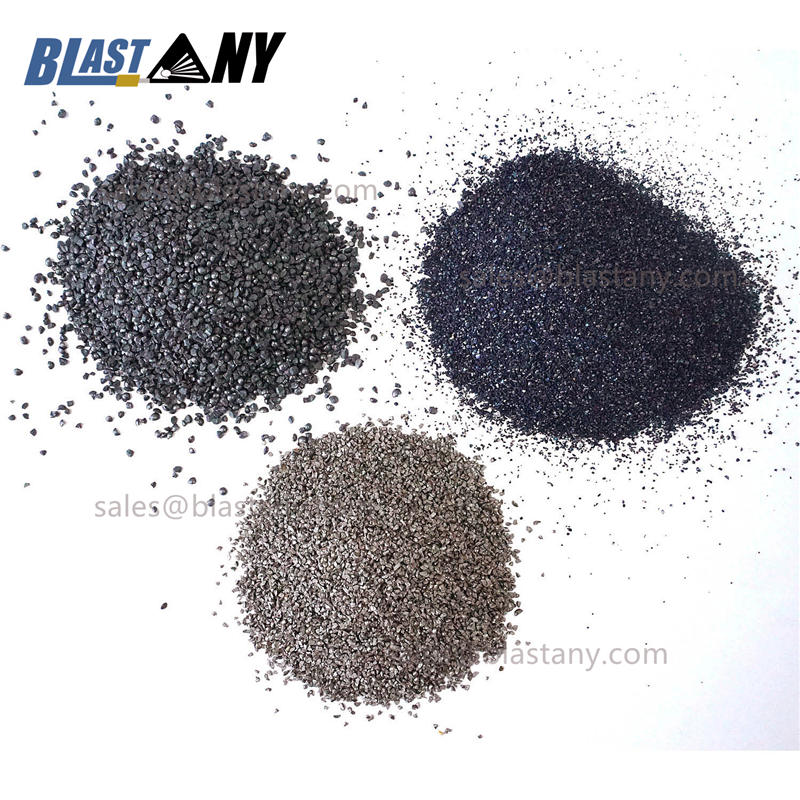

I-Junda Steel grit yobunzima obahlukeneyo

1.Igrit yentsimbi ye-GP: Le ntsimbi, xa isandula ukwenziwa, ibonakaliswe kwaye ifakwe iimbambo, kwaye imiphetho yayo kunye neekona zijikeleza ngokukhawuleza ngexesha lokusetyenziswa. Kufanelekile ngokukhethekileyo ukulungiswa kwangaphambili kwentsimbi yokususwa kwe-oxide.

2. I-GL grit: Nangona ubunzima be-GL grit buphezulu kune-GP grit, isalahlekelwa yimiphetho kunye neekona ngexesha lenkqubo ye-sandblasting kwaye ifaneleke ngokukodwa ukulungiswa kwangaphambili kokususa isikali se-oxide kwindawo yensimbi.

3.Isanti yentsimbi ye-GH: Olu hlobo lwesanti yentsimbi inobulukhuni obuphezulu kwaye iya kuhlala igcina imiphetho kunye neekona kumsebenzi wokuqhunyiswa kwesanti, okusebenza ngakumbi ukwenza umphezulu oqhelekileyo kunye noboya. Xa isanti ye-GH yentsimbi isetyenziselwa ukudubula komatshini wokuchama, iimfuno zokwakha kufuneka ziqwalaselwe ngokukhetha izinto zexabiso (ezifana nonyango lomqulu kwindawo yokusila ebandayo). Le grit yentsimbi isetyenziswa ikakhulu kwizixhobo zokukroba zomoya ezicinezelweyo.

Ukusetyenziswa kweshishini

Ukucoca igrit yentsimbi

I-steel shot kunye negrit zisetyenziselwa ukucoca izicelo zokususwa kwezinto ezikhululekile kwiindawo zetsimbi. Olu hlobo lokucoca luqhelekileyo kwishishini lemoto (iibhloko zeemoto, iintloko ze-cylinder, njl.)

Igrit yentsimbi Ukulungiswa komphezulu

Ukulungiswa komphezulu njengoluhlu lwemisebenzi equka ukucocwa kunye nokuguqulwa komzimba womphezulu. Ukudubula kwentsimbi kunye negrit zisetyenziswa kwinkqubo yokulungiselela umphezulu wokucoca imiphezulu yentsimbi egqunywe ngesikali sokusila, ubumdaka, umhlwa, okanye iipeyinti zokugquma kunye nokuguqula ngokwasemzimbeni umphezulu wesinyithi onjengokudala uburhabaxa ukuze kufakwe ipeyinti engcono kunye nokugquma. Izithonga zentsimbi zisetyenziswa ngokubanzi koomatshini bokuqhumisa.

Intsimbi yentsimbi Ukusika amatye

Igrit yentsimbi isetyenziselwa ukusika amatye aqinileyo, njengegranite. Igrit isetyenziswa kwiifreyimu ezinkulu ze-multi-blade ezisika iibhloko zegranite zibe ziziqwenga ezibhityileyo.

Igrit yentsimbi Shot ichama

Ukuchama ngokudutyulwa kukubethelwa okuphindaphindiweyo komphezulu wesinyithi ngamasuntswana okudubula okuqinileyo. Ezi mpembelelo ezininzi zivelisa i-deformation kumphezulu wesinyithi kodwa ziphucula ukuqina kwenxalenye yentsimbi. Usasazo olusetyenziswe kwesi sicelo lungqukuva kune-angular. Isizathu sesokuba izithonga ezingqukuva ziyakwazi ukumelana nokwaphuka okwenzeka ngenxa yempembelelo ebambekayo.

Igrit yentsimbi yokuqhushumba kweSanti

Umgangatho wegrit yentsimbi yeCarbon esetyenziselwa icandelo lomzimba wokuqhushumba kwesanti ichaphazela ngokuthe ngqo umgangatho kunye nexabiso elibanzi ngokwemigaqo yokusebenza kakuhle kwesanti yokuqhushumba, ukugquma kwebhanti, ukupeyinta, amandla e-kinetic kunye nokusetyenziswa kwe-abrasive. Ngomgangatho omtsha wokukhuselwa komgangatho wokusebenza (PSPC), kukho isicelo esiphakamileyo kwisiqwenga somgangatho wokuqhushumba kwesanti. Ke ngoko, umgangatho wegrit yentsimbi etyhidiweyo ubaluleke kakhulu kuqhushumbo lwesanti.

I-Angular shot ye-sandblasting Container

Intlabathi engqukuva yentsimbi engqukuva eqhumayo kumzimba webhokisi yebhokisi emva kokuba itshisiwe. Ukucoca i-welded joint kunye nexesha elifanayo ukwenza ibhokisi lomzimba webhokisi libe noburhalarhume obuthile kunye nokwandisa impembelelo yokudweba i-anti-corrosion, ukuze ukwazi ukusebenza ixesha elide phakathi kweenqanawa, i-chassis, isithuthi somthwalo kunye nomzila wesitimela.

Grit spherical for Izixhobo zombane wasendle zokuqhunyiswa kwesanti

Imveliso yombane wasendle inesicelo esikhethekileyo soburhabaxa kunye nokucoceka konyango lomphezulu .Emva konyango lomphezulu wegrit yentsimbi yentsimbi, kufuneka bangene kwiintlobo zotshintsho lwemozulu ngaphandle ixesha elide. Ke ngoko, igrit spherical sand blast for surface ibaluleke kakhulu.

Iiparamitha zobuGcisa

| SAE | Isicelo |

| G-12 | Ukuqhushumba/ukwehlisa intsimbi etyhidiweyo ephakathi ukuya kwenkulu, intsimbi ekhandiweyo, iingceba ezibunjiweyo, ipleyiti yentsimbi kunye namaqhekeza omsebenzi ancamatheleyo erabha. |

| G-18 | Ukusika/ilitye lokusila; Iziqwenga zokusebenza ezinamathele kwirabha eqhumayo; |

| G-50 | Ukuqhushumba / ukuhla kwentsimbi yentsimbi, isipanela, umbhobho wentsimbi ngaphambi kwenkqubo yokupeyinta; |

Amanyathelo eMveliso

Impahla engekasilwa

Ukufudumeza

Uvavanyo

Iphakheji

Iindidi zeemveliso