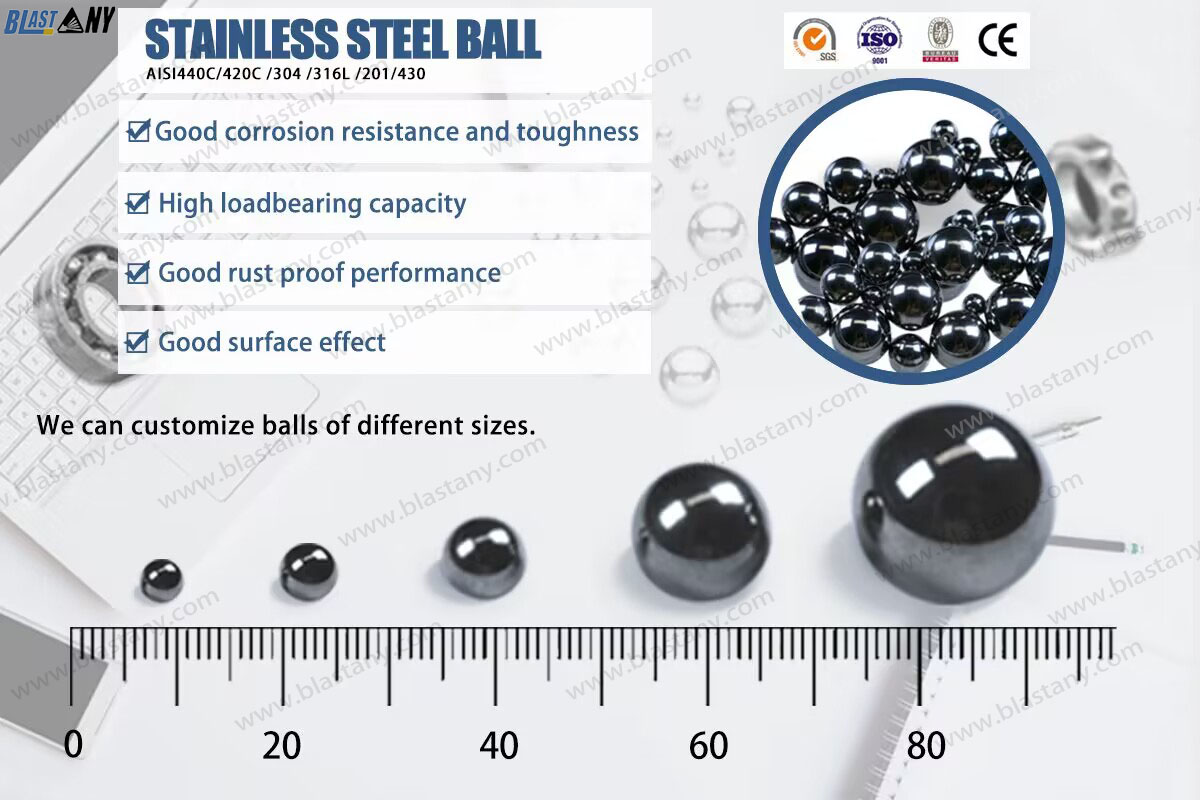

Ubonelelo lwefektri 0.35mm- 50.8mm HRC50-55 ukukhanya AISI304 316 430 440 ibhola yentsimbi engenastainless Isetyenziswa ekuBhereni

Ingcaciso yeMveliso

Iibhola ezingenasici ziyakwazi ukuxhathisa i-corrosion ngama-agent afana nezisombululo ze-oxidizing, uninzi lweekhemikhali eziphilayo, izinto zokutya kunye nezisombululo zokucoca. Ziyakwazi ukumelana ne-sulfuric acids. Iipropati ezingezizo ezemagneti ziyafumaneka xa uceliwe. Izicelo ziquka i-aerosol, izitshizi, iindlela zokumpompa iminwe, iiblenders zoomatshini bobisi, izixhobo zokulungisa ukutya kunye nezicelo zonyango.

I-AISI 440C Ibhola yensimbi engenasici

Ubungakanani: 0.35mm-50.8mm

Ibanga:G10, G16, G40, G60, G100, G200.

Ubunzima: I-HRC56-58, i-Hartford 440C iibhola zensimbi ezingenasici zidluliswa ukuze zisuse iintsholongwane zentsimbi zamahhala kwaye ziququzelele ukwakheka ngokuzenzekelayo kwefilimu ekhuselayo.

Imagnethi: Intsimbi yeMartensitic, kazibuthe

Iimpawu: ukuchaneka okuphezulu, ukuchasana kakuhle kwe-corrosion, i-rust eyomeleleyo kunye nokumelana nokunxiba.

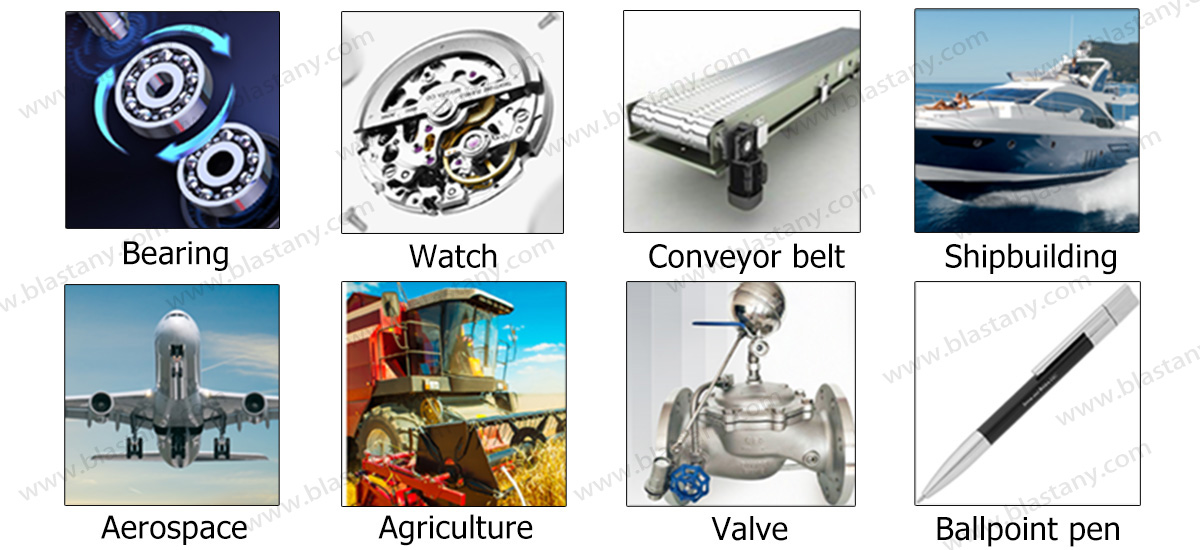

Usetyenziso: Iibheringi, isitampu, iinxalenye zehydraulic, iivalvu, i-aerospace, izitywina, izixhobo zesikhenkcisi, izixhobo ezichanekileyo, njl.

| Ukwakhiwa kweekhemikhali | ||||||||

| I-AISI 440C | C | Si | Mn | P | S | Ni | Cr | Mo |

| 0.95-1.10 | ≤0.80 | ≤0.80 | ≤0.04 | ≤0.03 | ≤0.60 | 16.0-18.0 | 0.75 | |

I-AISI 420C Ibhola yensimbi engenasici

Ubungakanani: 0.35mm-50.8mm

IBakala: G10-G1000

Ukuqina: HRC50-55

I-Magnetic: Intsimbi yeMartensitic, imagnethi, isakhono esilungileyo sokuchasa umhlwa, ubulukhuni obuphezulu, i-AISI 420 iibhola zentsimbi ezingenasici zibonisa iimpawu zokunxiba ezintle kunye nokuqina. Ubulukhuni obuncinci kunye nokumelana nomhlwa okukhulu, xa kuthelekiswa ne-440C.

Iimpawu: Eyaziwa ngokuba yintsimbi engatyiwayo, ukuxhathisa okulungileyo kokutya kunye nokuqina.

Izicelo: Zonke iintlobo zoomatshini abachanekileyo, iibheringi, izixhobo zombane, izixhobo zasekhaya, iinxalenye zemoto, njl.

| I-AISI 420C(4Cr13) | C | Si | Mn | P | S | Ni | Cr | Mo |

| 0.36-0.43 | ≤0.80 | ≤1.25 | ≤0.035 | ≤0.03 | ≤0.60 | 12.0-14.0 | ≤0.60 |

430 ibhola yensimbi engenasici

Ububanzi: 1MM-50.80MM

Ukuqina: HRC26

IBakala: G10-G1000

Iimpawu: ixabiso eliphantsi, ukunganyangeki kwe-rust.

Isicelo:i-hardware, imihombiso, izincedisi, izinto zokuthambisa, ishishini, amashishini aneemfuno eziphantsi zokusebenza kwe-antirust.Ii-cosmetics agitators, ipolishi yeenzipho kunye ne-eyeliners, izitshintshi zobushushu, izixhobo zokulinganisa. kunye neebhola zevalve.

| AISI 430 | C | Si | Mn | P | S | Ni | Cr | Mo |

| ≤0.12 | ≤1.0 | ≤1.0 | ≤0.04 | ≤0.03 | - | 16.0-18.0 | - |

I-AISI 304 Ibhola yensimbi engenasici

Ubungakanani: 0.5mm- 63.5mm

IBakala: G80-G500

Ukuqina: ≤HRC21

Imagnethi: Intsimbi yeAustenitic, engeyiyo imagnetic

Iimpawu: ukuxhathisa okuqinileyo kwe-rust, ukumelana ne-corrosion efanelekileyo.isetyenziswe ngokubanzi, ukusebenza kakuhle kobungqina be-rust, isiphumo esihle somgangatho, ukuqinisekiswa kokusingqongileyo.

Izicelo:Izixhobo zasekhaya ezinjengeevalvu, iibhotile zevumba elimnandi, ipolishi yeenzipho, iibhotile zeentsana, iintsimbi zemoto, izifudumezi-moya, izixhobo zombane, izithambiso, izilayidi, izixhobo zonyango, izacholo kunye namanye amashishini amaninzi.

| Ukwakhiwa kweekhemikhali | |||||||

| I-AISI 304 | C | Si | Mn | P | S | Ni | Cr |

| ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 8.0-10.5 | 18.0-22.0 | |

I-AISI 316L Ibhola yensimbi engenasici

Ubungakanani: 1.0mm-63.5mm

IBakala: G80-G500

Ukuqina: ≤HRC26

Imagnethi: Intsimbi yeAustenitic, engeyiyo imagnetic

Iimpawu: ezona zifanelekileyo kumashishini aneemfuno eziphezulu zokuchasana nomhlwa, kwaye amandla okuchasa umhlwa anamandla kakhulu,Ukumelana nokugqwesa ukubola (ngaphandle kwe-chloridric acids),Ayikho lukhuni i-austenitic inox

Usetyenziso: I-AISI 316L ibhola yensimbi engenasici ingasetyenziselwa izixhobo zonyango, ishishini lemichiza, inqwelomoya, i-aerospace, i-hardware yeplastiki, ibhotile ye-perfume, isitshizi, iivalvu, ipolishi yezikhonkwane, i-motor, switch, i-iron, oomatshini bokuhlamba, iifriji, i-air conditioners, izinto zonyango, ii-auto parts, iibheringi, isixhobo, ibhotile.

I-AISI 316L Ibhola yensimbi engenasici

| Ukwakhiwa kweekhemikhali | ||||||||

| I-AISI 316L | C | Si | Mn | P | S | Ni | Cr | Mo |

| ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 12.0-15.0 | 16.0-18.0 | 2.0-3.0 | |

Ukupakishwa kweMveliso

A) Ukupakisha kwangaphakathi: Ukupakisha okomileyo okanye ukupakisha ioli kubonelelwa ngokweemfuno zakho.

B) Ukupakishwa kwangaphandle:

1)igubu lentsimbi + ipalethi yomthi / yentsimbi.

2)25kg ipoly bag + ibhokisi + ipalethi yomthi okanye ibhokisi yomthi.

ukupakisha ngokwezifiso.

IParameter yeMveliso

| Ibhola yethu yeNsimbi engenaStainless ibandakanya i-440C 420C 304 316 201, Ukwakheka kweChemical kunje kulandelayo. | |||||||||

| Ukwakhiwa kweekhemikhali (%) | C | Cr | Si | Mn | P | S | Mo | Ni | Cu |

| Ibhola ye-AISI440C SS | 0.95-1.2 | 16-18 | ≤0.80 | ≤0.80 | ≤0.04 | ≤0.03 | ≤0.75 | ≤0.6 | ---- |

| Ibhola ye-AISI420C SS | 0.26-0.43 | 12-14 | ≤0.80 | ≤1.25 | ≤0.035 | ≤0.03 | ≤0.6 | ≤0.6 | ---- |

| Ibhola ye-AISI304 SS | ≤0.08 | 18-22 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | ---- | 8-10 | ---- |

| Ibhola ye-AISI316L SS | ≤0.08 | 16-18 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | 2.0-3.0 | 12-15 | ---- |

| Ibhola ye-AISI201 SS | ≤0.15 | 16-18 | ≤1.0 | 5.5-7.5 | ≤0.045 | ≤0.03 | ---- | 0.35-0.55 | 1.82 |

| Ibhola ye-AISI430 SS | ≤0.12 | 16-18 | ≤1.0 | ≤1.0 | ≤0.04 | ≤0.03 | ---- | ---- | ---- |

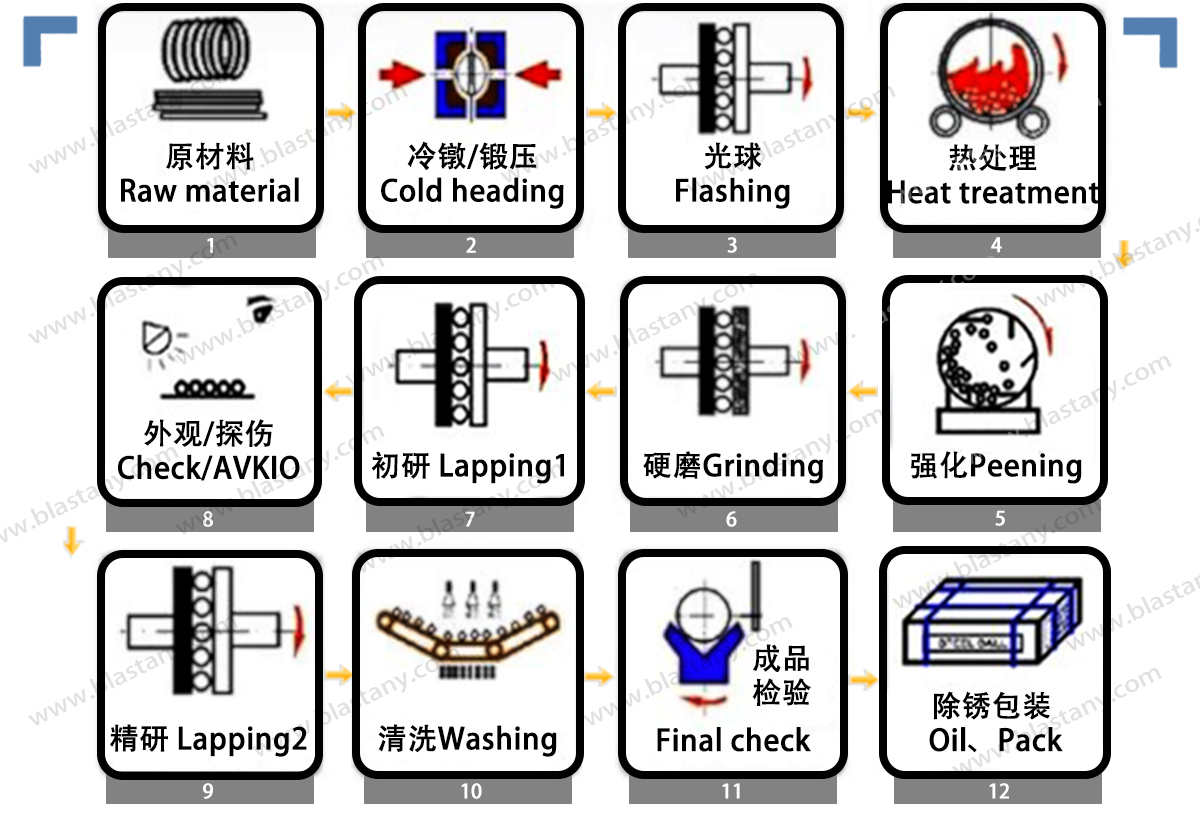

Ukuhamba kweMveliso

Ukuhlolwa kwezinto ezikrwada

Imathiriyeli ekrwada iza ngendlela yocingo. Okokuqala, imathiriyeli ekrwada ijongwa ngokubonakalayo ngabahloli bomgangatho ukuze baqinisekise ukuba umgangatho ufikelele kuphawu kunye nokuba kukho naziphi na imathiriyeli enesiphene. Okwesibini, qinisekisa ububanzi kwaye uphonononge izatifikethi zemathiriyeli ekrwada.

Isihloko esibandayo

Umatshini wesihloko esibandayo usika ubude obuchaziweyo bezinto zocingo kwi-slugs ye-cylindrical. Emva koko, iziqingatha ezibini ze-hemispherical zesihloko ziyafa zenza i-slug ibe yimilo erhangqayo. Le nkqubo yokubumba yenziwa kwindawo yokushisa kunye nexabiso elincinci lezinto ezongezelelweyo zisetyenziselwa ukuqinisekisa ukuba i-cavity yokufa igcwele ngokupheleleyo. Isihloko esibandayo senziwa ngesantya esiphezulu kakhulu, kunye nesantya esiphakathi sebhola enye enkulu ngomzuzwana. Iibhola ezincinci ziqhutywa ngesantya seebhola ezimbini ukuya kwezine ngomzuzwana.

Ukudanyaza

Ngethuba le nkqubo, izinto ezigqithisiweyo ezenziwe malunga nebhola ziya kukhutshwa. Iibhola zigqithiswa amatyeli aliqela phakathi kweepleyiti zentsimbi ezimbini ezikroliweyo zisusa isixa esincinci semathiriyeli engaphezulu njengoko ziqengqeleka.

Unyango lobushushu

Amalungu ke kufuneka aphathwe ubushushu kusetyenziswa iinkqubo zokucima kunye nokufudumeza.Isithando somlilo esijikelezayo sisetyenziselwa ukuqinisekisa ukuba zonke iindawo zithwala iimeko ezifanayo. Emva kokunyanga kokuqala kobushushu, iinxalenye zintywiliselwa kwindawo yokugcina ioli. Oku kupholisa ngokukhawuleza (ukucima i-oyile) kuvelisa i-martensite, isigaba sentsimbi esibonakaliswe ngobunzima obuphezulu kunye neempawu eziphezulu zokugqoka. Imisebenzi elandelayo yokuthoba inciphisa ngakumbi uxinzelelo lwangaphakathi de kufike umda wobulukhuni obuchaziweyo bokugqibela obuchaziweyo.

Ukusila

Ukugaya kwenziwa kokubili ngaphambi nangemva kokunyanga kobushushu. Gqiba UkuSila (okukwabizwa ngokuba yiHard Grinding) kusondeza ibhola kwiimfuno zayo zokugqibela.Ibakala lebhola yentsimbi echanekileyongumlinganiselo wokuchaneka kwayo iyonke; okukhona lisezantsi inani, kokukhona ichaneka ngakumbi ibhola. Umgangatho webhola ubandakanya ukunyamezelwa kwedayamitha, ukungqukuva (sphericity) kunye noburhabaxa bomphezulu obukwabizwa ngokuba kukugqitywa komphezulu. Ukwenziwa kwebhola echanekileyo ngumsebenzi webhetshi. Ubungakanani beqashiso bumiselwa kubungakanani bomatshini osetyenziselwa ukucola kunye nokusebenza ngokurhangqwa.

Ukuqhwalela

I-Lapping ifana nokusila kodwa inezinga elisezantsi kakhulu lokususa izinto. I-Lapping yenziwa kusetyenziswa iipleyiti zephenolic ezimbini kunye nodaka oluhle kakhulu oluludaka olufana nothuli lwedayimani. Le nkqubo yokugqibela yokuvelisa iphucula kakhulu uburhabaxa bomphezulu. I-Lapping yenziwa ngenxa yokuchaneka okuphezulu okanye amabakala ebhola achanekileyo.

Ukucoca

Umsebenzi wokucoca ke ngoko ususa naluphi na ulwelo olusetyenzwayo kunye nezinto ezishiyekileyo zokurhabula kwinkqubo yokwenziwa. Abathengi abacela iimfuno ezingqongqo ngakumbi zokucoca, njengalezo zikwiindawo ze-microelectronics, amashishini ezonyango okanye okutya, banokuthatha ithuba leHartford Technologies okukhethwa kukho okucokisekileyo kokucoca.

UHlolo Olubonwayo

Emva kwenkqubo yokwenziwa kweprayimari, iibhola ezininzi zentsimbi ezichanekileyo zijongwa ngeendlela ezininzi zokulawula umgangatho. Uhlolo olubonakalayo lwenziwa ukujonga iziphene ezifana nomhlwa okanye ukungcola.

I-Roller Gauging

I-roller gauging yi-100% yenkqubo yokuhlela eyahlula zombini iibhola zentsimbi ezichanekileyo ezingaphantsi kobukhulu kunye nobukhulu obungaphezulu. Nceda ujonge okwahlukileyo kwethuividiyo kwinkqubo yokulinganisa i-roller.

Ulawulo lwemeko

Iqashiso ngalinye leebhola ezichanekileyo ziyahlolwa ukuze kuqinisekiswe iimfuneko zebakala lokunyamezelana kwedayamitha, ukungqukuva kunye noburhabaxa bomphezulu. Ngethuba le nkqubo, ezinye iimpawu ezifanelekileyo ezinjengobunzima, kunye naziphi na iimfuno ezibonakalayo nazo zivavanywa.

Iindidi zeemveliso