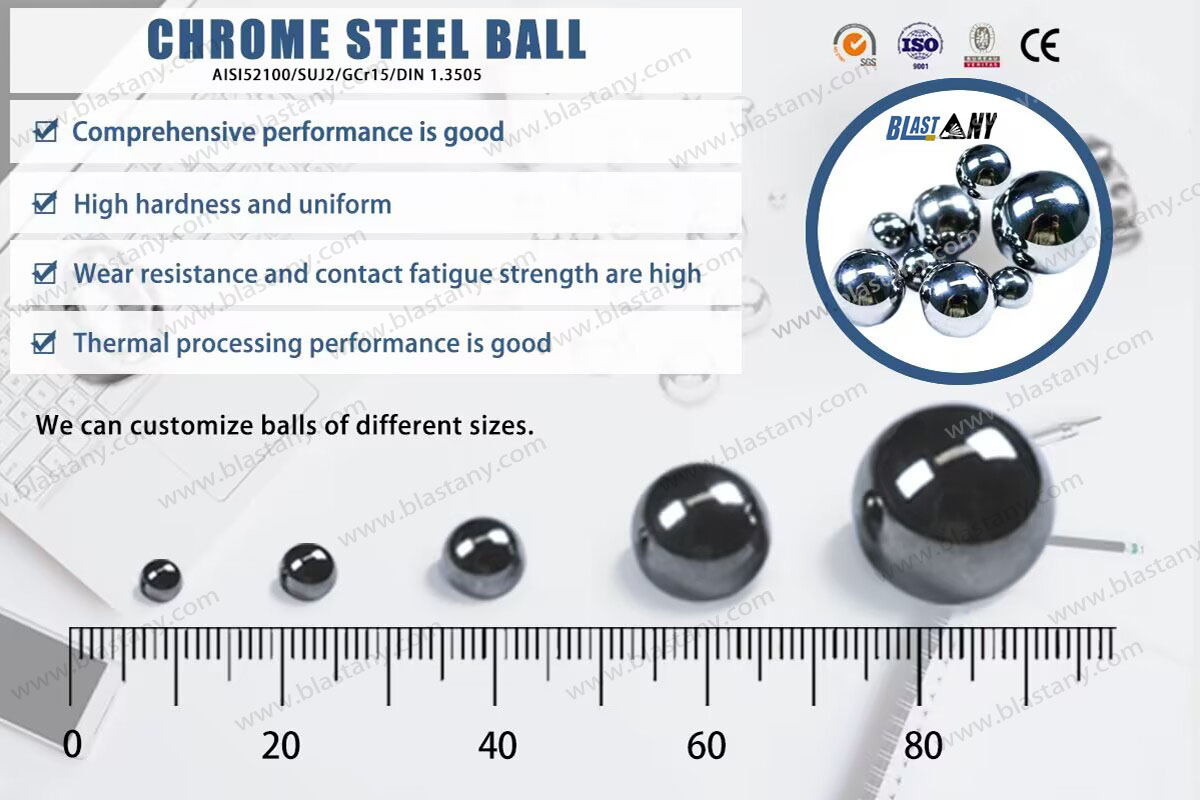

Umgangatho oPhezulu we-AISI52100 GCr15 4mm G10-G1000 iBhola yentsimbi yeChrome yesithuthuthu / iiNdawo zeBhayisekile/ iBhola

Ingcaciso yeMveliso

Ngenxa yeempawu zayo ezithile ezinjengokuqina okukhulu, ukumelana nokunxiba okuphezulu, ukugqiba kakuhle komphezulu kunye nokunyamezelwa komgangatho ophantsi, i-low-alloy martensitic AISI 52100 chromium steel isetyenziselwa ukwenziwa kweebheringi kunye neevalvu.

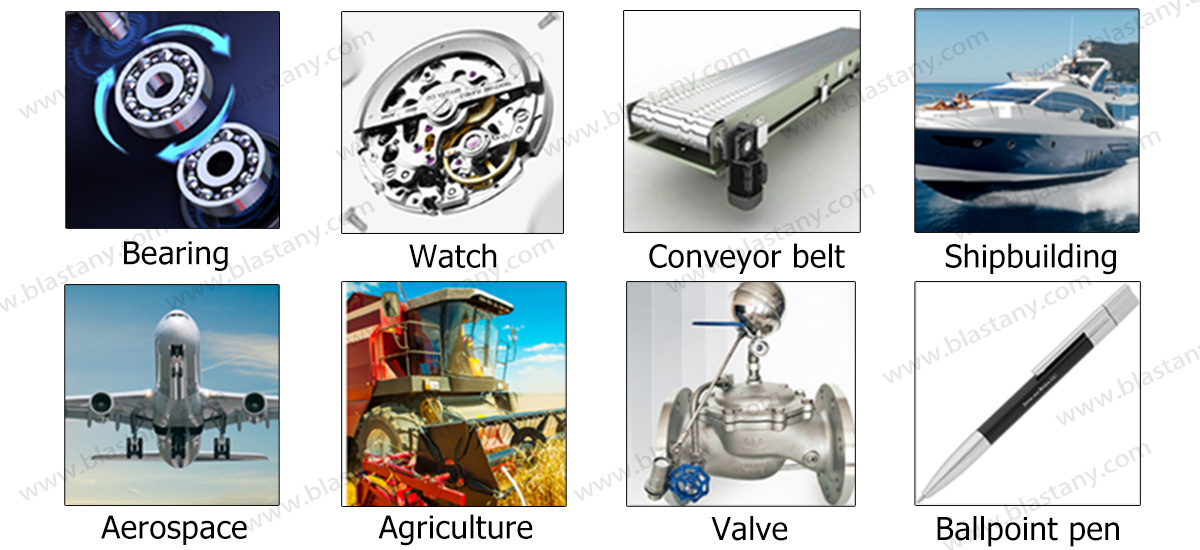

Iindawo zesicelo

Iibhola eziqengqelekayo, iiValuvu, iziqhagamshelo ezikhawulezayo, iibheringi zebhola ezichanekileyo, iinxalenye zemoto (iziqhoboshi, ukuqhubela phambili, ukuhanjiswa), iibhayisekile, iinkonkxa ze-aerosol, izikhokelo zedrowa, izixhobo zomatshini, iindlela zokutshixa, iibhanti zokuhambisa, izihlangu zesilayidi, iipeni, iimpompo, amavili ajikelezayo, izixhobo zokulinganisa, izikrufu zombane zendlu.

uluhlu lweparameter

| Ibhola yentsimbi yeChrome | |

| Izinto eziphathekayo | AISI52100/SUJ2/GCr15/DIN 1.3505 |

| Ubungakanani Uluhlu | 0.8mm-50.8mm |

| IBanga | G10-G1000 |

| Ukuqina | HRC: 60-66 |

| Iimbonakalo | (1)Intsebenzo ebanzi ilungile. (2)ubunzima obuphezulu kunye neyunifomu. (3) Ukumelana nokunxiba kunye namandla okudibana nokudinwa kuphezulu. (4) Ukusebenza kwe-Thermal processing kulungile. |

| Isicelo | Ibhola ethwele i-Chrome isetyenziselwa ikakhulu ukuvelisa iibhola zentsimbi, iirola kunye neehlahla kwii-shafts zokuqhuba ezifana neenjini zokutsha zangaphakathi, ii-locomotives zombane, izixhobo zoomatshini, iitrektara, izixhobo zokuqengqeleka, izixhobo zokomba, izithuthi zikaloliwe kunye noomatshini basemigodini. |

| Ukwakhiwa kweekhemikhali | ||||||

| 52100 | C | Si | Mn | P | S | Cr |

| 0.95-1.05 | 0.15-0.35 | 0.25-0.45 | 0-0.025 | 0-0.020 | 1.40-1.65 | |

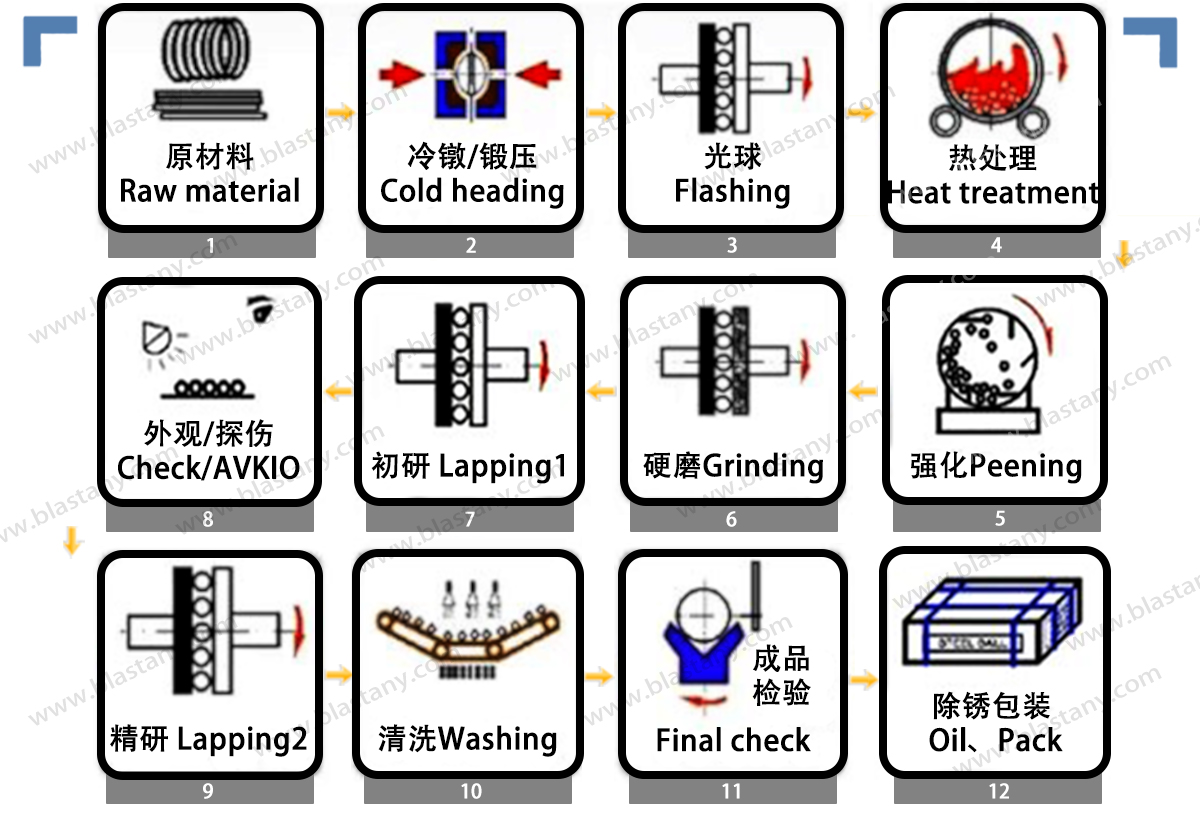

Inkqubo yokuvelisa

Ukuhlolwa kwezinto ezikrwada

Imathiriyeli ekrwada iza ngendlela yocingo. Okokuqala, imathiriyeli ekrwada ijongwa ngokubonakalayo ngabahloli bomgangatho ukuze baqinisekise ukuba umgangatho ufikelele kuphawu kunye nokuba kukho naziphi na imathiriyeli enesiphene. Okwesibini, qinisekisa ububanzi kwaye uphonononge izatifikethi zemathiriyeli ekrwada.

Isihloko esibandayo

Umatshini wesihloko esibandayo usika ubude obuchaziweyo bezinto zocingo kwi-slugs ye-cylindrical. Emva koko, iziqingatha ezibini ze-hemispherical zesihloko ziyafa zenza i-slug ibe yimilo erhangqayo. Le nkqubo yokubumba yenziwa kwindawo yokushisa kunye nexabiso elincinci lezinto ezongezelelweyo zisetyenziselwa ukuqinisekisa ukuba i-cavity yokufa igcwele ngokupheleleyo. Isihloko esibandayo senziwa ngesantya esiphezulu kakhulu, kunye nesantya esiphakathi sebhola enye enkulu ngomzuzwana. Iibhola ezincinci ziqhutywa ngesantya seebhola ezimbini ukuya kwezine ngomzuzwana.

Ukudanyaza

Ngethuba le nkqubo, izinto ezigqithisiweyo ezenziwe malunga nebhola ziya kukhutshwa. Iibhola zigqithiswa amatyeli aliqela phakathi kweepleyiti zentsimbi ezimbini ezikroliweyo zisusa isixa esincinci semathiriyeli engaphezulu njengoko ziqengqeleka.

Unyango lobushushu

Amalungu ke kufuneka aphathwe ubushushu kusetyenziswa iinkqubo zokucima kunye nokufudumeza.Isithando somlilo esijikelezayo sisetyenziselwa ukuqinisekisa ukuba zonke iindawo zithwala iimeko ezifanayo. Emva kokunyanga kokuqala kobushushu, iinxalenye zintywiliselwa kwindawo yokugcina ioli. Oku kupholisa ngokukhawuleza (ukucima i-oyile) kuvelisa i-martensite, isigaba sentsimbi esibonakaliswe ngobunzima obuphezulu kunye neempawu eziphezulu zokugqoka. Imisebenzi elandelayo yokuthoba inciphisa ngakumbi uxinzelelo lwangaphakathi de kufike umda wobulukhuni obuchaziweyo bokugqibela obuchaziweyo.

Ukusila

Ukugaya kwenziwa kokubili ngaphambi nangemva kokunyanga kobushushu. Gqiba UkuSila (okukwabizwa ngokuba yiHard Grinding) kusondeza ibhola kwiimfuno zayo zokugqibela.Ibakala lebhola yentsimbi echanekileyongumlinganiselo wokuchaneka kwayo iyonke; okukhona lisezantsi inani, kokukhona ichaneka ngakumbi ibhola. Umgangatho webhola ubandakanya ukunyamezelwa kwedayamitha, ukungqukuva (sphericity) kunye noburhabaxa bomphezulu obukwabizwa ngokuba kukugqitywa komphezulu. Ukwenziwa kwebhola echanekileyo ngumsebenzi webhetshi. Ubungakanani beqashiso bumiselwa kubungakanani bomatshini osetyenziselwa ukucola kunye nokusebenza ngokurhangqwa.

Ukuqhwalela

I-Lapping ifana nokusila kodwa inezinga elisezantsi kakhulu lokususa izinto. I-Lapping yenziwa kusetyenziswa iipleyiti zephenolic ezimbini kunye nodaka oluhle kakhulu oluludaka olufana nothuli lwedayimani. Le nkqubo yokugqibela yokuvelisa iphucula kakhulu uburhabaxa bomphezulu. I-Lapping yenziwa ngenxa yokuchaneka okuphezulu okanye amabakala ebhola achanekileyo.

Ukucoca

Umsebenzi wokucoca ke ngoko ususa naluphi na ulwelo olusetyenzwayo kunye nezinto ezishiyekileyo zokurhabula kwinkqubo yokwenziwa. Abathengi abacela iimfuno ezingqongqo ngakumbi zokucoca, njengalezo zikwiindawo ze-microelectronics, amashishini ezonyango okanye okutya, banokuthatha ithuba leHartford Technologies okukhethwa kukho okucokisekileyo kokucoca.

UHlolo Olubonwayo

Emva kwenkqubo yokwenziwa kweprayimari, iibhola ezininzi zentsimbi ezichanekileyo zijongwa ngeendlela ezininzi zokulawula umgangatho. Uhlolo olubonakalayo lwenziwa ukujonga iziphene ezifana nomhlwa okanye ukungcola.

I-Roller Gauging

I-roller gauging yi-100% yenkqubo yokuhlela eyahlula zombini iibhola zentsimbi ezichanekileyo ezingaphantsi kobukhulu kunye nobukhulu obungaphezulu. Nceda ujonge okwahlukileyo kwethuividiyo kwinkqubo yokulinganisa i-roller.

Ulawulo lwemeko

Iqashiso ngalinye leebhola ezichanekileyo ziyahlolwa ukuze kuqinisekiswe iimfuneko zebakala lokunyamezelana kwedayamitha, ukungqukuva kunye noburhabaxa bomphezulu. Ngethuba le nkqubo, ezinye iimpawu ezifanelekileyo ezinjengobunzima, kunye naziphi na iimfuno ezibonakalayo nazo zivavanywa.

Iindidi zeemveliso